Insect-like soft robots: is 3D printing changing robotics?

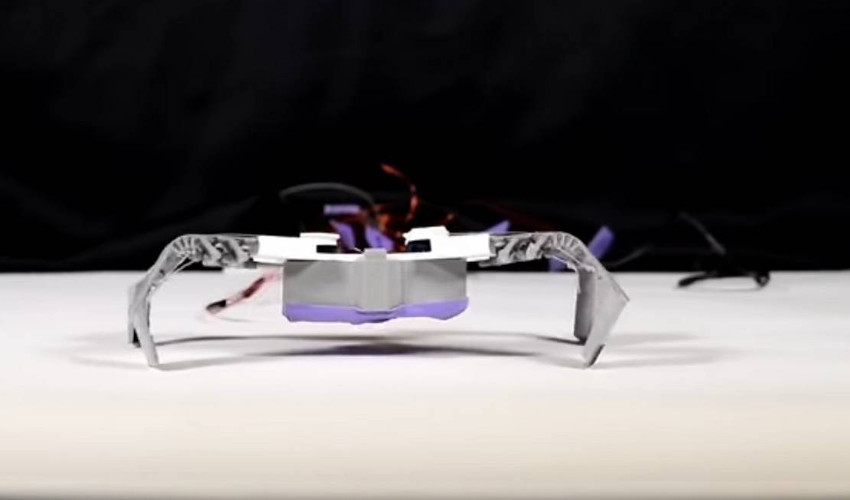

It should not come as a surprise that additive manufacturing is widely used in the field of robotics. 3D printing offers designers the freedom to add new functionalities to their creations. We have covered topics related to AM in robotics before, like the time when researchers created 3D printed sweating robot muscle at the University of Cornell. This time, the big news come from UC San Diego where researches have designed and successfully tested 3D printed insect-like soft robots. Soft robotics is actually a subfield of robotic which deals with the construction of robots from highly compliant materials, similar to those found in living organisms. Using FDM 3D printers, and standard filament materials such as ABS, the researchers created insect-like robots that were significantly cheaper as well as more accessible.

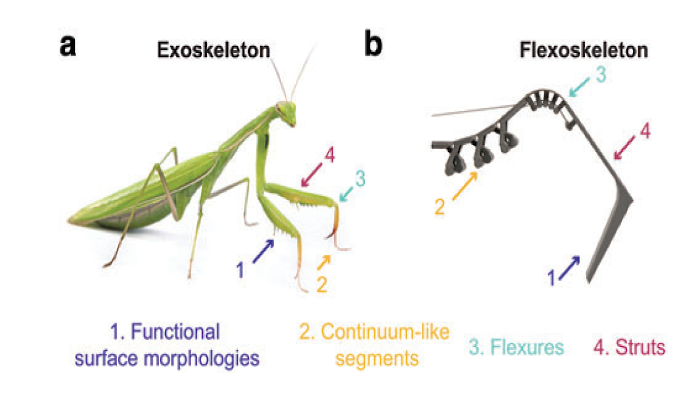

The innovation by engineers at the Jacobs School of Engineering at UC San Diego comes from rethinking the way soft robots are built: instead of figuring out how to add soft materials to a rigid robot body, the researchers did the reverse. They started with a soft body and added rigid features to key components. The structures were inspired by insect exoskeletons, or rather how they function, such exoskeletons are rigid in some places, but perfectly flexible in others.

Credits: Soft Robotics

Additively manufacturing the insect-like robots

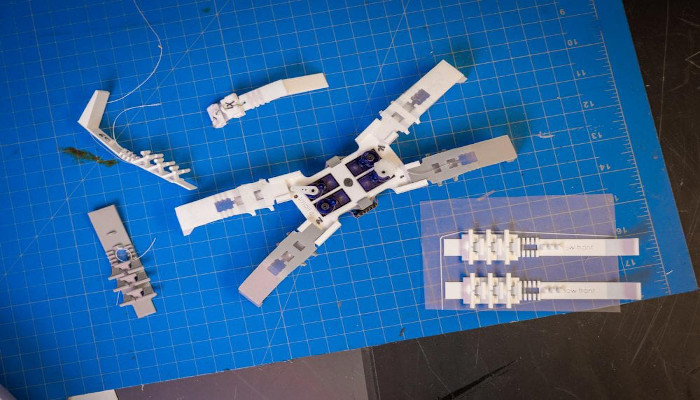

In standard FDM printing, a plastic filament such as ABS or PLA is extruded through a heated nozzle and deposited onto a flat print surface. The innovative flexoskeleton process uses Prusa i3 MK3S or the LulzBot Taz 6 FDM 3D printers, to deposit filament directly onto a heated thermoplastic base layer. This results in high bond strength between the deposited material and the flexible base, yielding improved resistance.

According to the researchers, the printing process takes around 10 minutes to produce a single Flexoskeleton, which can be done using almost any 3D printer on the market and requires less than $1 in materials! In total, it takes less than three hours to fabricate and assemble a functioning robot. This impressively fast and cheap method also makes it possible to build rather large groups of flexoskeleton robots with little manual assembly, as well as assemble a whole library of Lego-like parts so that robot parts can be easily swapped if damaged, or when they wear out. The completed bot was able to reach a speed of nearly 5cm per second during testing. “The ultimate goal is to create an assembly line that prints whole flexoskeleton robots without any need for hand assembly. A swarm of these small robots could do as much work as one massive robot on its own-or more,” said Nick Gravish, a mechanical engineering professor at the Jacobs School of Engineering at UC San Diego who oversees the project.

This innovation can potentially have significant implication for more than just one industry – the budget-minded AM technique could not only lower the cost of entry for 3D printing soft robotics, but also open new applications for the technology in places that, for example, are not safe for humans, such as navigating disaster or war zones.

What do you think about the insect-like soft robots? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!