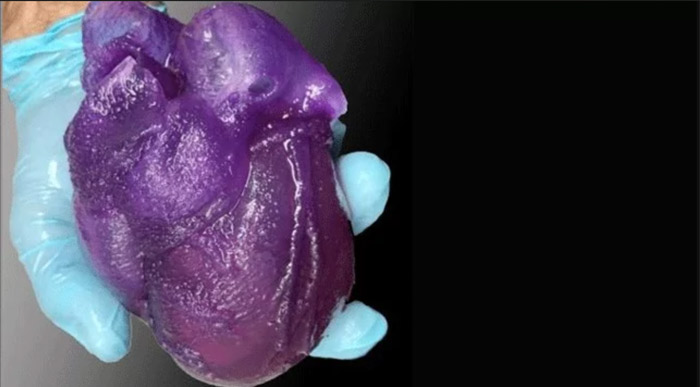

Researchers develop 3D printed human heart model for surgical planning

At Carnegie Mellon University in Pittsburgh, a team of researchers has developed a printing method called FRESH (Freeform Reversible Embedding of Suspended Hydrogel), which is able to produce a human heart model to help surgeons in their operations. Using alginate as the material, this process allows to reproduce the soft and elastic aspect of organ tissues: when pressed or squeezed, the heart deforms, just like a real human heart. Therefore, this technique makes the model a much more realistic medical tool, allowing surgeons to practise, for example, stitching, which would be impossible on impenetrable plastic models.

Recent progress made in the bioprinting sector is increasingly impressive: today, many players use additive manufacturing techniques to extrude cells and design living tissue, gradually moving towards the creation of fully functional human organs. Even if there is still a lot of progress to be made before a bioprinted organ is implanted in a patient, recent projects are encouraging. On the other hand, 3D printing has become a perfect method to make custom anatomical models, helping healthcare professionals to better prepare for an operation, or to better understand how the human anatomy works. Essentially, it allows to recreate a patient’s organ using data from an MRI. Some 3D printing technologies are so precise that they can reproduce vascularization, and other complex parts.

The 3D printed heart model

Reproducing the elasticity of human heart tissue

Carnegie Mellon University wanted to develop a method to mimic the very texture of the human heart, i.e. the soft and elastic aspect of its tissues. The researchers explained that they used alginate, a soft material derived from marine algae, which also proved to be very accessible cost wise. They used a FDM 3D printer, but instead of extruding the model onto an open air build plate, they deposited the material layer by layer in a gelatin container.

Adam Feinberg, biomedical engineer and co-author of the research, adds: “Imagine printing inside a styling gel and think of the little bubbles suspended in the bottle: the gel provides enough support for them to float indefinitely, or at least until you take the gel out of the bottle. In our case, the gel provides enough support for the needle of the 3D printer to slide in. Everything you extrude can then stay in place.” Once the organ is printed, researchers have to get rid of the layer of gelatin that surrounds it. It’s a material that melts on contact with heat, so simply raising the mixture’s temperature removes the gel from the 3D printed structure.

Adam Feinberg has been using additive manufacturing for a few years now.

Such a 3D printed alginate heart would cost only $10, which could enable several hospitals to implement this technology. Adam Feinberg explains that he would like to test other materials such as collagen, which would create an even more realistic solution. But for now, collagen is still too expensive: the same heart would indeed cost $2,000! Adam Feinberg explains: “We think there are a number of applications where the realism of collagen is probably worth it. But when you’re doing research in the lab – and if you make a lot of mistakes in developing the technology – it’s better to use a cheaper material, hence the choice of alginate.”

Towards an even more realistic 3D printed heart

In addition to this model of a human heart, the team reported it used the same 3D printing technique to design a coronary artery. The objective was to see if it would be perfusable and capable of circulating blood. By pumping fake blood, it would appear that the artery maintained the fluid: this could be a first step towards creating a heart with an interconnected vascular system. Surgeons could then practice stitching the arteries under operating room like conditions.

What this team of researchers really hopes to achieve is to introduce cells into the 3D printed heart in order to make it beat. The culture of these cells has already started in the laboratory, but today, only 100 million cells could be placed in the printed organ at the same time, compared to 100 billion needed for a normal sized heart. You can find more information HERE.

What do you think of this latest research project at Carnegie Mellon University? Let us know in a comment below or on our Facebook and Twitter page! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!