Are 3D printed helmets becoming the norm?

In the world of sports, additive manufacturing technologies can offer many benefits to athletes. Sporting equipment can be custom-made, geometrically more complex and made from smarter materials. Over time, manufacturers have understood the benefits of integrating 3D printing pieces in their equipment as a means to offer more functionality and higher performance. This has been demonstrated by leading companies such as Adidas – the company developed 3D printed soles for its running shoes – or Riddell, which developed 3D printed liners for its helmets.

In fact, helmets are one of the sports equipment that have developed most in recent times. Riddell, HEXR, and Kupol, have all integrated additive manufacturing to their design process. The companies have explained before that one of the key reasons for adoption is the great amount of protection that can be added. For example, HEXR creates helmets that have a 3D printed curved honeycomb structure made from PA 11 that can absorb shocks much more effectively. The structure is perfectly adapted to the wearer’s head because it is modeled according to its shape. In the case of Riddell, the helmet liners are made using Carbon technology, which enables elastomer lattice structures – known to handle high impact shocks very well – to be 3D printed and customized to fit an athlete’s head perfectly.

HEXR creates helmets that have a 3D printed curved honeycomb structure | Credits: HEXR

KAV, a startup based in California, manufactures helmets for hockey players, and uses 3D printing technologies too. Just like other sports companies, its mission is to provide protective equipment that is also high performing. It decided to use 3D printing as part of its design workflow and manufacturing process after identifying the lack of personalization and size variation in traditional hockey helmets. However, KAV also aims to make its helmets accessible to most, and for this reason it uses FDM technology. In the case of Riddell for example, using Carbon’s CLIP technology, which is similar to SLA, is expensive.

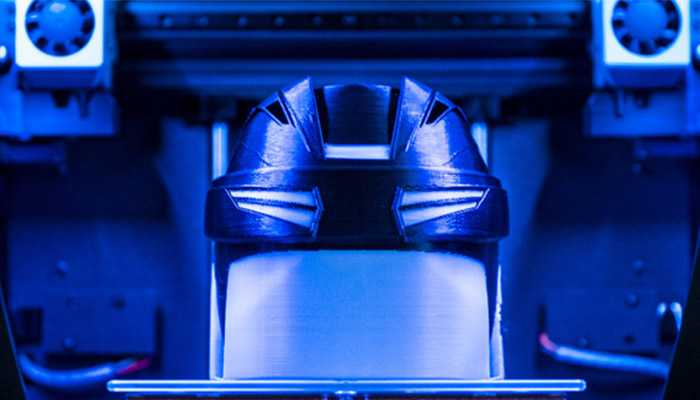

The hockey helmet manufacturer has worked with BCN3D and leveraged their IDEX technology to create designs that can be reviewed and impact tested by athletes in a matter of days. The company uses the platform to get tailored helmets, reducing the expense of tooling and opening up the use of novel structures. The inside of the helmets is made from advanced carbon polymers and thanks to machine learning algorithms they use, they are able to optimize material placement. As a result, the weight of the helmet is reduced. Moreover, KAV has simplified the design, eliminating the standard two-shell mechanism.

KAV creates designs that can be reviewed and impact tested by athletes in a matter of days | Image via BCN3D

The example of KAV is only one of many. Nevertheless, when you consider the number of players in the sports industry, there are still few that have fully adopted 3D printing for their equipment, even though this is changing. We cannot wait to discover the new applications that 3D printing will bring to this industry! You can find more information about KAV’s 3D printed helmets HERE.

What do you think of 3D printed helmets? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter to receive all the latest 3D printing news straight to your inbox!

I enjoyed reading this. I believe 3d printed helmets are the future. The first generation has some compromises, particularly on price, but like electric cars, the best is yet to come!