New 3D Printed Gummies Combat Nutritional Deficiencies

Imagine having a gummy made just for you, with the right amount of iron, vitamin D or any other nutrient your body needs. A team of researchers from the Universitat Politècnica de València (UPV), in collaboration with the University of Foggia in Italy and Jiangnan University in China, has developed a 3D printing system for gummies enriched with customized micronutrients. Their study, published in the scientific journal Journal of Food Engineering, opens up new possibilities for nutrition.

Malnutrition due to a lack of micronutrients, such as iron, zinc and B vitamins, affects a third of the world’s population, according to the WHO. Some of the causes are deficient diets, absorption problems or limited access to a variety of foods. Faced with this problem, the possibility of manufacturing personalized foods according to the nutritional needs of each person is seen as a great answer.

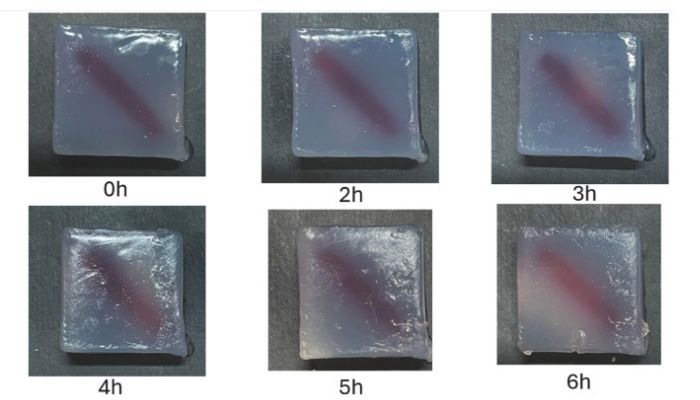

Photographs of the 3D gummies showing their storage for 6 hours at room temperature (Credits: Adrián Matas-Gil et al.).

The Role of 3D Printing

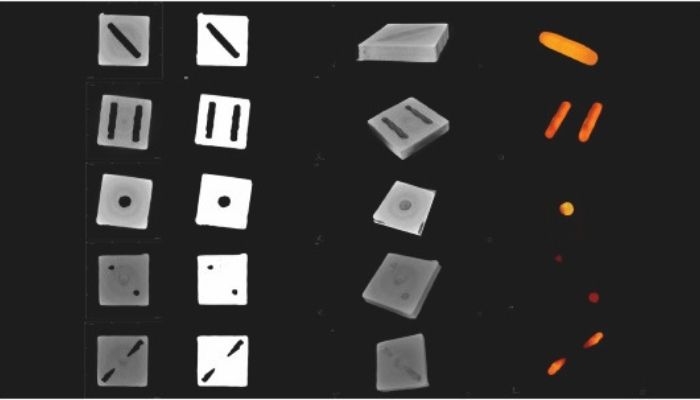

The purpose of the gummies is to improve health. They are made from a starch gel called Ultratex, derived from tapioca and agar. The gummies have adaptable internal structures where nutrients can be introduced as necessary. The key to the development lies in the precision that 3D printing allows. Using software, users can define both the shape and the exact amount of nutrients they want to include in the gummies. The system translates this information into a digital design that is then printed with a nozzle as small as 0.4 mm in diameter, maintaining high fidelity between the model and the physical result. For the tests, the scientists used the Foodbot chocolate 3D printer.

During testing, the team found that the gummies can retain nutritional quality, and their texture is adequate. They are easy to chew and remain stable for several hours. This could facilitate their distribution even through vending machines, as suggested by the scientists. Xavier Martínez Monzó, researcher at the University Institute of Food Engineering-FoodUPV, states: “The results we have obtained so far are very positive. We are still working to improve some aspects, but this work is a new advance in the application of 3D printing in the food industry for the health of consumers.”

X-ray images of the 3D gummies show the fidelity of the print and its microstructural features (Credits: Adrián Matas-Gil et al.).

One point that makes the scientists’ proposal stand out is that their system allows precise dosing in the preparation of the gummies. Unlike other approaches that mix ingredients in fixed proportions, their method allows precise dosing of small amounts of micronutrients, avoiding waste and ensuring greater efficiency. In addition, gels such as starch-agar ensure good flowability and rapid solidification. This is essential for the quality of the printed gummies.

Although the system is already functional, the team continues to refine aspects, such as the solidity of the internal cavities and the long-term stability of the nutrients incorporated. They are also analyzing new tests to improve the resolution of the process and adapt the materials to other dietary needs. If you want to know all the research details, consult the study HERE.

What do you think of the 3D printed gummies? Let us know in a comment below or on our LinkedIn and Facebook pages. Plus, sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel. Interested in more medical and dental 3D printing news? Visit our dedicated page HERE.

*Cover Photo Credit: Universitat Politècnica de València

Unlike other approaches that mix ingredients in fixed proportions, their method allows precise dosing of small amounts of micronutrients, avoiding waste and ensuring greater efficiency. In addition, gels such as starch-agar ensure good flowability and rapid solidification. This is essential for the quality of the printed gummies.