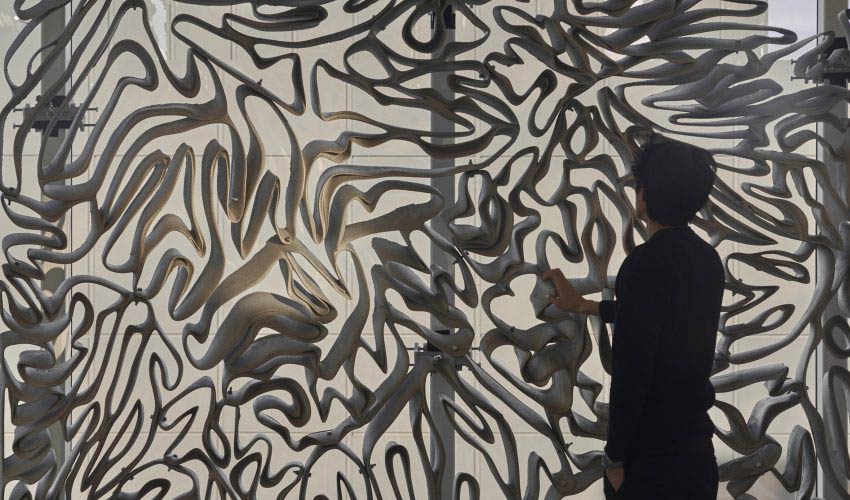

A complex metal facade made with 3D printed molds

Students from the University of Applied Sciences, ETH Zurich, created a 6 meter high, 4 meters wide metal facade from 3D printed molds. Called ‘Deep Facade’, it was made by assembling 26 articulated metal panels.

The use of 3D printing to create all kinds of artistic works is now a common practice, with many artists having surpassed certain limits thanks to these 3D technologies – especially in terms of geometric freedom. They offer much more complexity in forms and opportunities for customization, especially in the architectural sector. The facade created by the students of ETH Zurich is a good illustration.

3D printed molds to create the structure

Deep Facade is an aluminum structure, composed according to its creators of sorts of metal ribbons that connect to each other in an organic way, so as to recall the folds of the cerebral cortex. It was done as part of a course in architecture and digital manufacturing in order to link the geometric freedom offered by 3D printing to the structural properties of cast metal. Aghaei Meibodi, a researcher at ETH Zurich explains, “Cast metal parts have a long tradition in architecture due to their extraordinary structural properties and possible 3D form. Today, the amount of manual labor involved, especially in the mold-making process makes them too expensive. With our approach using a 3D-printed mold, we make it possible and affordable again to fabricate bespoke structural metal parts — parts with unseen richness of detail and geometric complexity,”

The structure was designed thanks to 3D printed molds, a method of manufacturing that is much faster and economical for students. They used an ExOne 3D printer, which is based on powder binding technology. By combining 3D printing with topological optimization, they were able to create custom-made, lightweight metal parts with a high level of complexity. They commented that “This approach can unlock an entirely new vocabulary of shapes for metal structures in architecture, previously unavailable with traditional mold-making systems.”

Deep Facade mimics the development of certain living organisms and evokes the liquid appearance and strength of the metal compared to other materials such as sandstone or concrete. You can find the entire manufacturing process in the video below or on the ETH Zurich official website:

What do you think of the Deep Facade structure? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!