Researchers 3D print multi-material electric motor

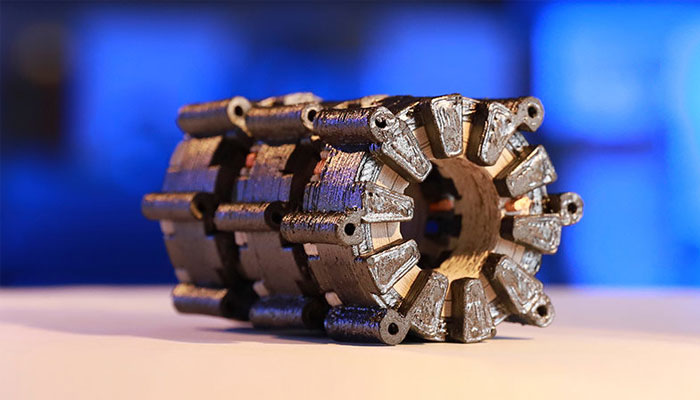

After two years of research, electrical engineers from the Chemnitz University of Technology have succeeded in designing a functional electric motor using additive manufacturing from iron, copper, and ceramics. A multi-material engine that illustrates the full potential of 3D printing!

Additive manufacturing has enabled a number of new engine concepts to emerge, whether for rockets, trucks or to design reactor prototypes. 3D technologies offer considerable advantages in terms of performance, customization, manufacturing time and cost. This time, it is German engineers who claim to have 3D printed an electric motor from 3 different materials.

A 3D printed electric motor

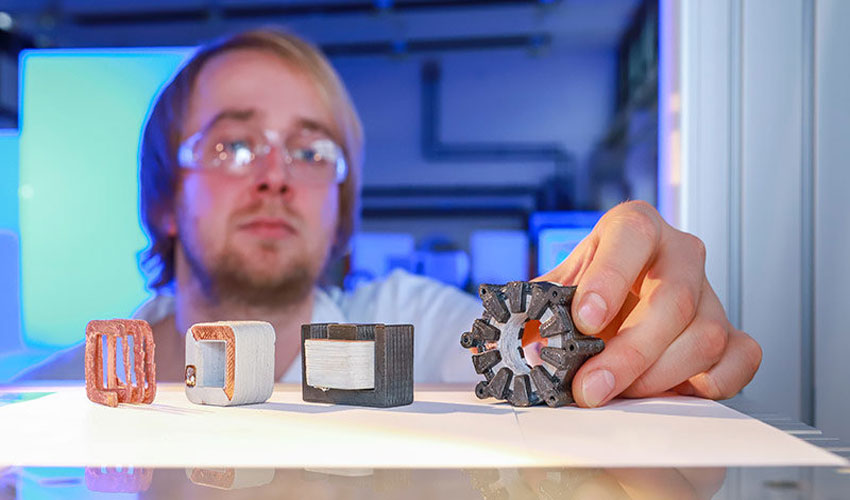

The engineering team has been working on this project for the last few years and in addition to their creating engine during this time, they have also managed to squeeze in the development of a printing filament, able to withstand temperatures of more than 300° C. With their filament, they used selective laser sintering to create, layer-by-layer, a functional engine. This engine includes copper electrical conductors that create magnetic fields with iron, but also electrical ceramic insulation that insulates conductors from each other and iron components.

“Our goal over the last two and a half years was to dramatically increase the temperature that electrical machines are capable of withstanding,” says professor Ralf Werner, who led the study. He goes on to explain that they have achieved this goal by replacing the traditional polymer-based insulation with a type of ceramic that is more heat-resistant. The ceramic insulating material would also have a higher degree of thermal conductivity so that the heat losses generated in the conductors could be dissipated more quickly. This allows researchers to increase the output density of electrical machines.

The printing process developed by the researchers is based on the extrusion of highly viscous pastes, layer by layer. These pastes consist of particles of the desired materials, such as iron, copper or ceramics but also suitable binders. Researchers say they have worked with ViscoTec to achieve the highest level of accuracy during extrusion of materials.

Find all the information about the 3D printed engine on the University’s website.

What do you think of this 3D printed electric motor? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!