The 3D Printed Drones Helping Fight Wildfires

Public safety technology developer Axle Box Innovations is using additive manufacturing to support the development of 3D printed drones for fire management and protection. In recent years, wildfires have become an increasing threat in the United States and other countries in the world, destroying numerous homes and entire communities and causing billions of dollars in damages. In 2021, 8,619 wildfires burned almost 2.6 million acres, making it a record year for wildfires in American forests. Axle Box turned to 3D printing to help solve strength, speed and cost obstacles in the creation of fire-safe drones.

In order to be able to counter the growing number of fires, firefighters are relying more and more on innovative technologies such as additive manufacturing. When facing a new wildfire outbreak, it is essential for firefighters to get an accurate view of the situation. To access the situation quickly, firefighters need special drones, which have the ability to get close to the flames and analyze the extent of the outburst, notably counting the number of fires present in certain areas. Unfortunately, common commercial drones aren’t suitable to get close enough to wildfires, because their material and technical equipment cannot withstand the high temperatures.

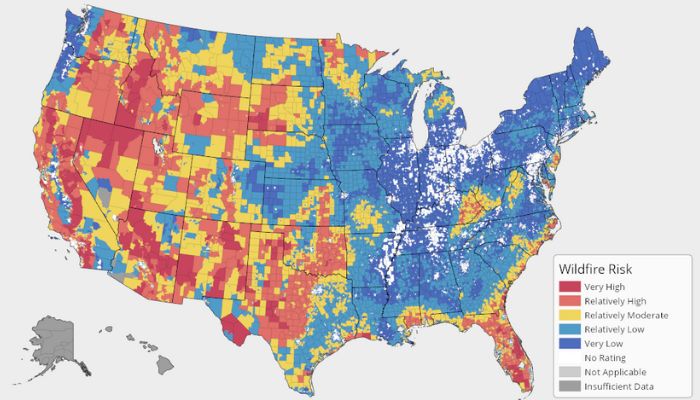

A map showing the areas with the highest risk of wildfires. Wildfires have increased over the years especially in dry areas like the West due to global warming (photo credits: FEMA)

Creating Fire-Safe Drones

In search of the right technologies and materials for the development of heat-resistant drones, the engineers at Axle Box came across the solutions offered by Essentium. Blake Teipel, Ph.D., CEO of Essentium commented: “As first responders gear up for fire season, firefighters need nimble remote-controlled drones to achieve visual oversight of wildfires in virtually every type of environment – from urban areas to rural deserts. We are excited Axle Box Innovations has chosen our 3D printing platform to enable the development of structurally rugged drones that can withstand these extremely harsh conditions.”

The material used for the creation of the heart-resistant drones is a high-temperature nylon with a 25% carbon fiber core. It will be used for the drone’s mid-body as well as its side covers, which will make sure the drone will maintain its shape and functions during its exposure to high levels of heat. Beyond being inherently heat resistant, the material also allows for the creation of lightweight and robust drone bodies, critical components when it comes to both flying and safety applications. For the actual manufacturing process, Axle Box chose Essentium’s HSE 3D Printer, which uses an independent dual extrusion (IDEX) system and filaments.

Photo Credits: National Archives at College Park – Still Pictures

Madison Jones, director of additive manufacturing at Axle-Box, concluded: “The speed, scale, and economics of the HSE 3D Printer combined with Essentium’s array of advanced 3D printing filaments are changing the game for the design and development of drone platforms. The HSE has transformed our manufacturing floor, and we typically go from design to production in under four weeks. If we need a new part, we can have one printed and up in the air in a couple of hours. Our first responder customers will benefit greatly from this innovation agility.” When exactly the drones will be ready to be of aid in the fight against wildfires is yet to be revealed, but with the right technologies and materials already at hand, the production is most likely to be finalized sometime soon. To find out more in the press release HERE.

What do you think of the production of 3D printed drones to help firefighters? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.