New 3D printed swabs: self-adjusting for a less painful COVID-19 testing

Some COVID-19 testing methods are not the most pleasant: virological testing (RT-PCR) can be very uncomfortable for many patients. A nasal swab is inserted quite deep into the nose to take a nasopharyngeal swab. A team of engineers from the School of Engineering at the University of Wolverhampton redesigned the swab to make it more comfortable. Using 3D printing technology and meta-materials, they were able to design a smart little device that self-adjusts to each patient, reducing the discomfort and possible pain caused. For the moment, the novel 3D printed swabs are only used in the labs.

As you already know, additive manufacturing has been of great help during the global health crisis. It has helped our caregivers, hospitals, and patients, by designing and producing respirators, ventilators, visors, etc. AM has also been contributing to the testing procedures by additively manufacturing test tubes and swabs. For instance, Carbon and Formlabs 3D print thousands of swabs a day! And now it’s the University of Wolverhampton that has come up with an innovative solutions to fight against COVID: 3D printed swabs that are 3D printed with an interesting choice of material – the university researchers have opted for meta-materials, which are artificial materials with significant electromagnetic properties. Dr. Arjunan, one of the team’s researchers, explains: “This research is the first step in starting an open and collaborative process to drastically improve the existing concepts in nasopharyngeal swabs using the principles of digital fabrication and meta-materials. The opportunity to digitally conceive and 3D print swabs allows for the incorporation of geometrical features that can potentially reduce patient discomfort.“.

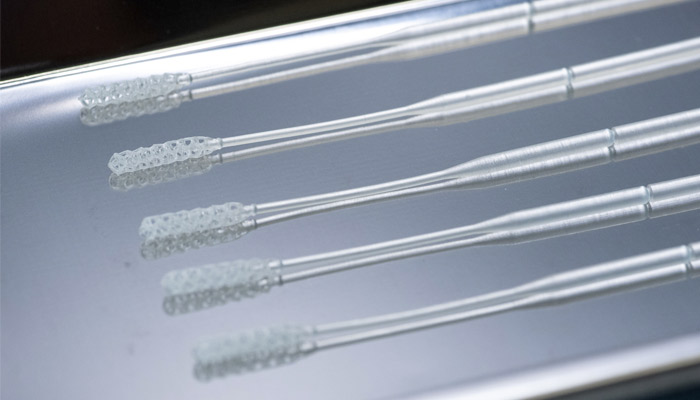

Many companies have been actively 3D printing thousands of swabs for COVID-19 testing. (Image credits: Origin)

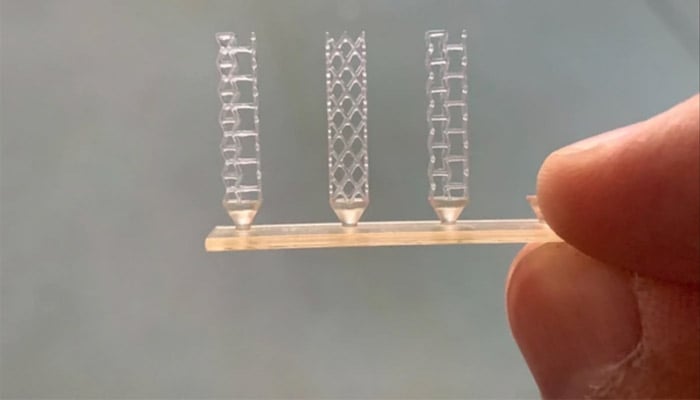

Researchers have therefore developed a 3D printed auxetic swab, capable of retracting under the effect of axial resistance. The researchers explain: “This allows the swab to navigate through the nasal cavity with significantly less stress on the surrounding tissues. In comparison, a traditional material will tend to expand under axial load causing discomfort and stress in surrounding tissues”. An auxetic material has a negative Poisson’s ratio, which means that when it gets stretched, it becomes thicker perpendicular to the stretching force. The team remains discreet about the specifics of the design phase of this self-adjusting swab – we simply know that it worked in partnership with Formlabs to carry out the first tests. In any case, it is the material that enables these retraction and adaptation properties of the swabs.

The team points out that they still have some work to do before moving on to a large-scale production phase. Dr. Arjunan concludes: “The study is likely to take another six months before it can be used in test centres, however the benefits of the swab go beyond the COVID crisis as these smart swabs are superior to traditional swabs because they significantly reduce patient discomfort and can be printed on demand.” Overall, the researchers hope that they will be able to 3D print these swabs on demand as soon as possible.

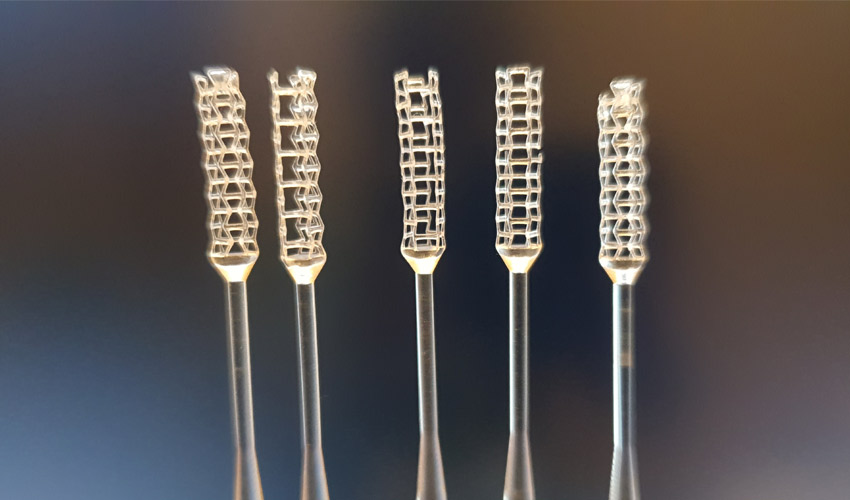

A unique material allows swabs to retract. (Image credits: University of Wolverhampton)

What do you think about the self-adjusting nasal swabs as a way to make the COVID-19 tests less painful? Let us know in a comment down below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!