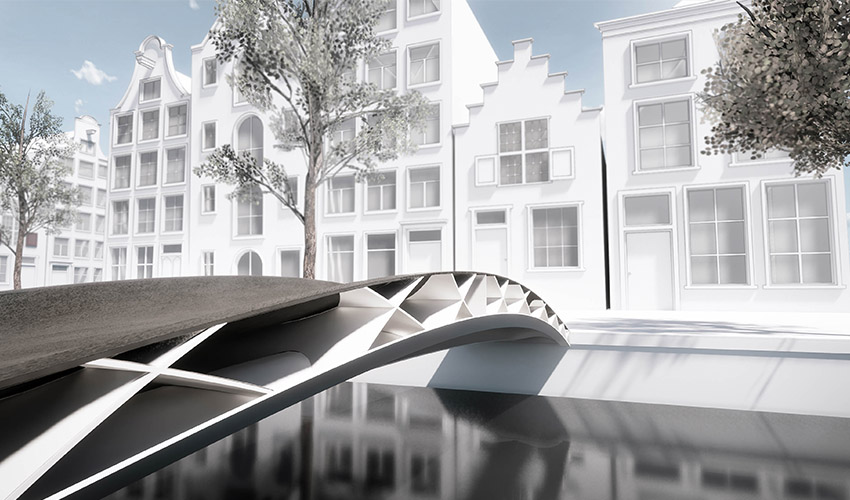

First lightweight 3D printed bridge prototype is versatile and sustainable

The first lightweight 3D printed bridge prototype has been designed for pedestrian use by Royal HaskoningDHV, CEAD and DSM. The three companies are working together to lead a revolution in bridge construction and design, showcasing how leading companies in the Netherlands are partnering to be at the forefront in the transition towards a more circular economy.

Royal HaskoningDHV is an international engineering and project management consultancy, DSM, a global science-based company in nutrition, health and sustainable living and pioneer in 3D printing materials, and CEAD, supplier of 3D printing equipment on the frontier of large-scale composite additive manufacturing.

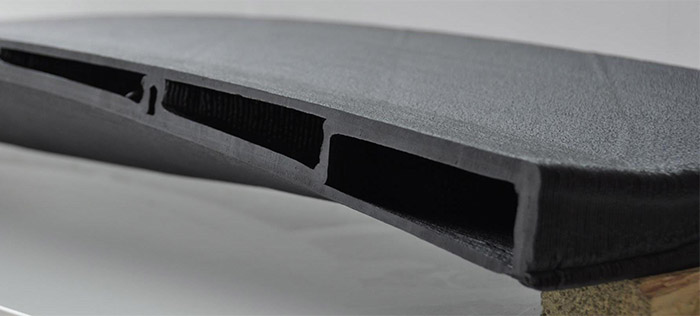

The bridge was made from composite material, consisting of a glass filled thermoplastic PET that is combined with continuous glass fibers which are added in the 3D printing process. This unique combination offers high strength with extreme versatility and sustainability. Fiber Reinforced Polymer (FRP) bridges are already known for having a longer lifetime expectancy with lower life cycle costs compared to steel bridges.

First lightweight 3D printed bridge prototype

Patrick Duis, Segment Leader Additive Manufacturing at DSM added: “Using a material such as Arnite (PET) has huge benefits for the construction of bridges. Rather than using traditional materials such as steel or concrete, these bridges can be much more sustainable and offer greater flexibility in design using recyclable materials. We know that designs previously deemed challenging or impossible to produce with other manufacturing methods are now possible with 3D printing, and we’re excited to be playing our part in this partnership.”

Maurice Kardas, Business Development Manager at Royal HaskoningDHV explains: “What’s new here is the use of a new 3D printing technology, enabling us to print large scale continuous fiber reinforced thermoplastic parts. Using this new composite thermoplastic material, we will be ushering in a new era for sustainability and push the boundaries of bridge functionality even further.”

It is not just the technology that is innovative, it’s also the design freedom achieved. Combining the companies’ generative design and predictive modelling expertise broadened the design freedom. It’s clear that 3D printing has evolved dramatically over the years and what is possible today was impossible some years ago. Now, the construction sector is starting to take full advantage of the technology and we have seen a number of players within the industry adopt additive manufacturing.

Maarten Logtenberg concludes: “This 3D printed bridge prototype demonstrates the huge strides that we are making which will transform the future of this industry, not only speeding up construction, but also making the process more cost and time efficient. We developed this technology for exactly these industry applications, making them more sustainable and easier to manufacture.”

You can find more information HERE.

What do you think of this 3D printed bridge prototype? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!