UNSW Scientists use new bioink to create 3D printed bone

Scientists from the University of New South Wales (UNSW Sydney), a leading research and teaching university in Australia, have developed a ceramic-based ink that could allow surgeons to create 3D printed bone parts with actual living cells. We’ve seen recently that 3D printing is becoming increasingly popular in the medical field, with implants notably earning the most attention as 3D printing allows doctors and scientists to create more personalised biomedical devices for patients. The ink itself would be a huge advancement due to the presence of living cells, ultimately hopefully allowing surgeons to include implants in the operating room.

How it works

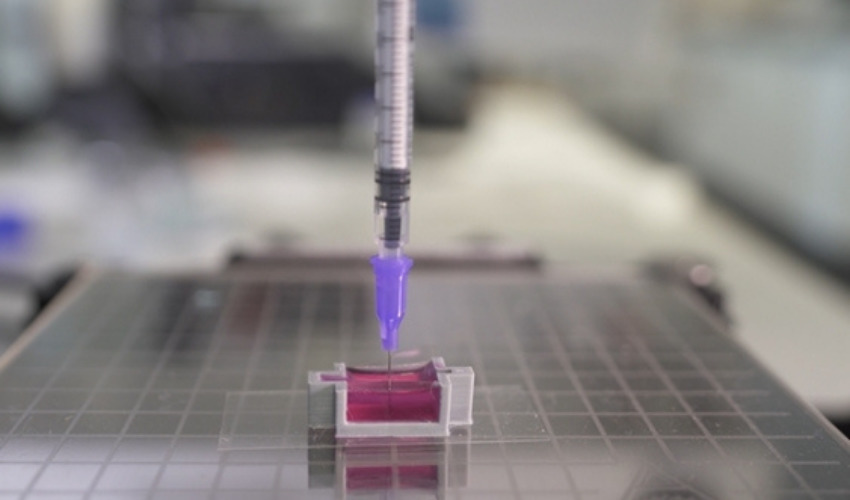

The project could be classified as bioprinting, a method enabling cellular structures to be made from bioinks loaded with stem cells. Essentially, it works similarly to many additive manufacturing methods, where cells and biomaterials are combined and then deposited layer by layer with the ultimate goal being to create biomedical models with the same properties as living tissues. Over the past few years there have been huge advancements in the field. Already, laboratories have started bioprinting human livers, kidneys and hearts. It’s not even the first time that we have seen 3D printing being used for implants in the medical field, with numerous examples in bone implants alone. However, the ability to add living cells to a 3D printed structure already would make this a huge step forward for the technology.

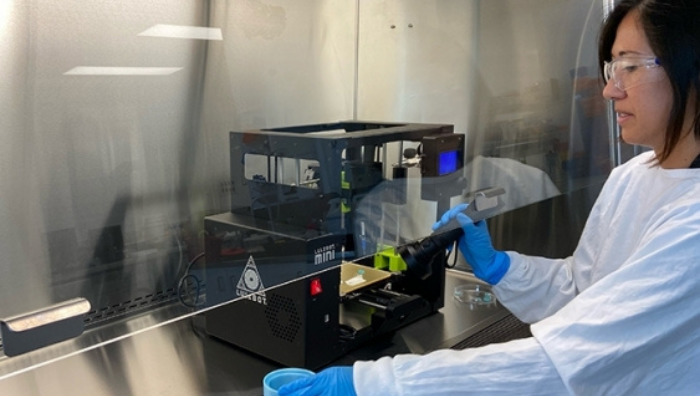

A scientist from the project prepares to 3D-print a piece of bone using the COBICS technique. (photo credits: UNSW)

Dr. Iman Roohani from UNSW’s School of Chemistry, one of the scientists working on this project commented “This is a unique technology that can produce structures that closely mimic bone tissues. It could be used in clinical applications where there is a large demand for in situ repair of bone defences such as those caused by trauma, cancer, or where a big chunk of tissues is resected.” This is the first time that 3D printed bone-mimicking structures can be created at room temperature and complete with living cells without using harsh chemicals according to Roohani. The scientists used a special ink made out of calcium phosphate, a compound used in supplements as a way to help treat calcium deficiencies. This ink was used in a 3D printer using a special technique that they developed named ceramic omnidirectional bioprinting in cell-suspensions (COBICS), enabling them to make bone-like structures that hardened when placed in water.

Why 3D printing?

The new ink plays on one of the most attractive attributes of 3D printing, the ability to customize and build parts on the spot that will be a better fit than a traditionally manufactured piece. According to Associate Professor Kristopher Kilian who worked on the project, “The cool thing about our technique is you can just extrude it directly into a place where there are cells, like a cavity in a patient’s bone. We can go directly into the bone where there are cells, blood vessels and fat, and print a bone-like structure that already contains living cells, right in that area.”

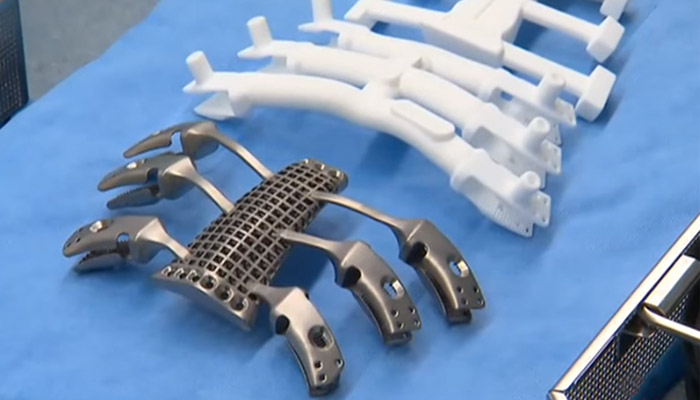

Previous projects in replacing bone through 3D printing has used titanium. The ability to put in bone with real cells would be a huge advancement in bioprinting. (photo credits: 7News Australia; Anatomics)

According to Roohani, the ink combined with a collagenous substance containing living cells enables in-situ fabrication of bone-like tissues. These could have many applications, notably in bone tissue engineering, disease modeling, drug screening and in-situ reconstruction of bone and osteochondral defects. Kilian added, “I imagine a day where a patient needing a bone graft can walk into a clinic where the anatomical structure of their bone is imaged, translated to a 3D printer, and directly printed into the cavity with their own cells. This has the potential to radically change current practice, reducing patient suffering and ultimately saving lives.”

Though it is not certain how (the duo needs to perform in vivo tests in animal models to see if the living cells will continue to grow even after being implanted in existing bone tissue), this is a significant step forward in the industry. Maybe in the near future surgeons will be using 3D printers directly in the operating room, providing implants that are made specifically for the patient, resulting in more successful post-operative results. For more information on the project, check out the video of the process below.

If you are interested in learning more, check out the press release HERE. What do you think about the new bioink? Do you think we’re close to having 3D printed bones? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!

*Thumbnail photo credits: UNSW