Particle3D is creating tailor-made 3D printed bone implants

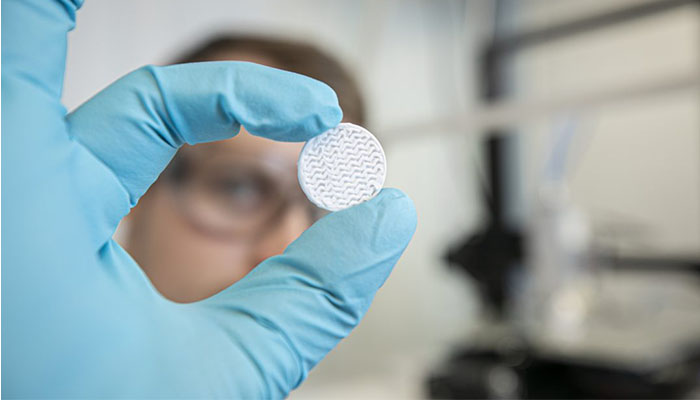

The Danish company, Particle3D, uses a proprietary technology to create 3D printed bone implants that are tailored to a patient’s body. Additionally, the implants are porous and degradable which means that they fuse to a patient’s skeleton before disappearing. Founded in 2014, the company has come a long way in the development of these implants. Today, Particle3D’s fabrication method and bone material has been validated through various studies and tests from researchers worldwide.

Bone tissue reconstruction is a surgery performed millions of times each year for people that have congenital bone defects, victims of accidents or cancer patients. In the world of additive manufacturing, many attempts have been made at developing a viable solution for these people. For example, a team of researchers at the University of Arizona was combining 3D printing with adult stem cells to create biomimetic scaffolds that could treat fractures. In the case of Particle3D, it is using a bioink made from tricalcium phosphate (TCP) particles that stimulate natural bone growth, and fatty acids.

Image via Particle3D

The Danish company explains that TCP is often used in similar cases, however the implants are made manually from solid blocks which limit their usefulness. Moreover, in such a process the implant is not perfectly adapted to the patient’s body. This is why Particle3D starts with scans of the patient’s bones, enabling the creation of a tailor-made 3D printed implant. Just like any 3D model that needs to be printed, the data from the scan is fed to CAD software and then adjusted in order to be optimized for surgery. Particle3D takes care of the production process, leaving the insertion in the hands of the hospital it sends the implant to.

As you will have understood, its proprietary technology is what allows TCP to be 3D printed into not any implant, but into a porous and degradable medical device. You can read on their website: “Particle3D has developed a technology to reconstruct the patient’s exact anatomy with 3D printed patient-fitted implants with bone-like porosity. The implants are made from natural biomaterials which degrade over time and remodel into real living bone tissue.”

Image via Particle3D

For the future, the company has said that it expects its implants to be able to deliver additives, including growth factors antibiotics and chemotherapy. This is a very exciting step for tailor-made medicine, and also a reminder that a growing number of advancements in this sector are taking place. It seems to be just a question of time before solutions such as these are implemented on a wider scale. You can find more information HERE.

What do you think of these implants? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter to receive all the latest 3D printing news straight to your inbox!