Will the 3D printed bone bricks facilitate the healing of complex fractures?

The treatment of an orthopaedic bone fracture can be very complex, and usually requires a metal rod or plate to be placed in the body to stabilize the bone. Scaffolding materials encapsulated in powders or paste are then injected into the bone to heal it. These usually tough and risky steps can now be made easier with additive manufacturing: researchers at Oregon Health and Science University (OHSU), in collaboration with a team from New York University and Mahidol University in Thailand, have developed a 3D printed scaffolding system, no larger than a Lego brick. These small 3D-printed bone bricks can be placed precisely where they are really needed and encourage the growth of neighboring cells.

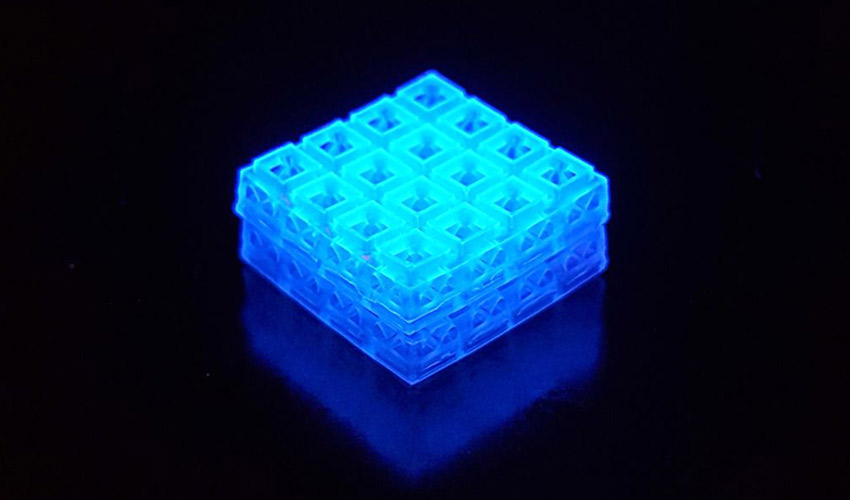

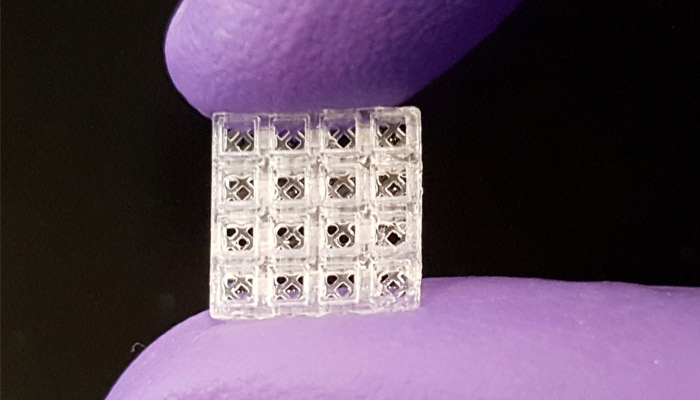

Additive manufacturing has often contributed to the development of more efficient medical scaffolding, better adapted to each research, treatment, etc. It should be remembered that it is a microenvironment that promotes cell growth: in 3D, it takes the form of a matrix on which cells can cling and grow in the best conditions. In our case, the researchers opted for a shape similar to that of the famous Lego, with small holes inside. Ramesh Subbiah, PhD, a postdoctoral researcher at the OHSU laboratory, explains: “The 3D-printed microcage technology improves healing by stimulating the right type of cells to grow in the right place, and at the right time. Different growth factors can be placed inside each block, enabling us to more precisely and quickly repair tissue.”

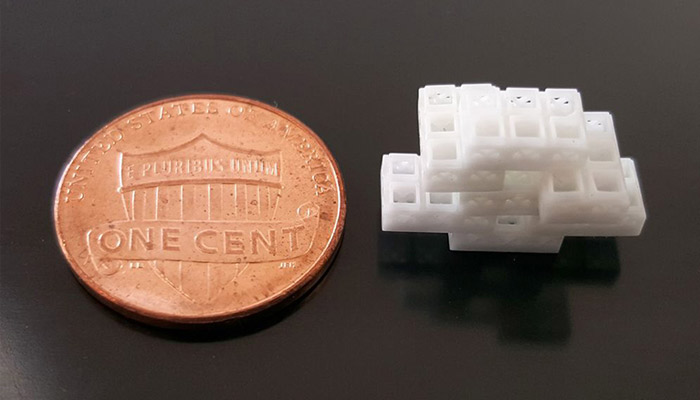

The 3D printed tiny cubes can be attached to each other (Image credits: OHSU)

The team of researchers 3D printed several tiny 1.5 mm cubes made up of hollow micro-cages. The tiny holes are there to be loaded with different bio-gel compositions in a completely controlled manner, creating scaffolding on which hard and soft tissue can grow back. These cubes would also be able to nest together to form thousands of different combinations. Dr. Luiz Bertassoni, the team leader and associate professor at OHSU, adds, “Our patent-pending scaffolding is easy to use, it can be stacked together like Legos and placed in thousands of different configurations to match the complexity and size of almost any situation.” According to the team, they used lithography-based ceramic manufacturing (LCM) 3D printing technique with beta-tricalcium phosphate ceramic.

So far, this scaffolding system has reportedly been tested on rat bones; the results are promising as these 3D printed bone bricks led to around three times more blood vessel growth than traditional scaffolding material! It thus seems to be very useful for tissue regeneration. Finally, the team says that by working with four layers of 4×4 blocks, they could obtain more than 29,400 different combinations, which shows that this scaffolding system can be easily customized for each patient. More information can be found HERE.

Image credits: OHSU

What do you think about the 3D printed bone bricks? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!