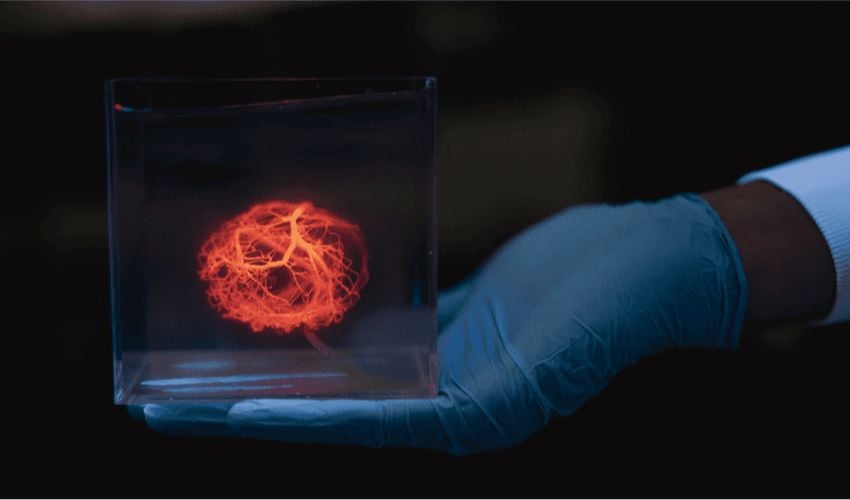

3D Printed Blood Vessels, A Step Towards Artificial Organs

The shortage of organs available for transplantation remains a major issue: demand far exceeds supply. In the United States, there are more than 100,000 people on organ transplant lists, and some might wait years to receive one, if they survive the wait. Faced with this shortage and the risks associated with graft rejection, regenerative medicine is exploring innovative solutions. In particular, scientists are striving to create tailor-made organs, produced from a patient’s own cells, to respond more rapidly and efficiently to needs.

Researchers at Stanford University recently reached a key milestone. They developed an advanced technique enabling blood vessels to be designed and 3D printed with great precision and speed. This breakthrough addresses one of the major challenges in creating personalized organs from a patient’s cells.

Photo Credits: Freepik

Complex Blood Vessels Recreated Using 3D Printing

For an organ to function, blood must circulate from large arteries to tiny vessels, where it feeds the cells. Cells need to be very close to the capillaries to survive – sometimes less than a hair’s breadth away, especially in organs like the heart. In one cubic millimeter of heart tissue, there can be over 2,500 capillaries, all connected to each other before leaving the organ. As each organ has a unique shape, creating a suitable network of vessels is complex and slow. Until now, researchers have often used simple, standard vascular models, effective for small tissues but unsuitable for larger, more varied organs.

A Stanford team developed a method for creating the complex 3D networks of blood vessels found in organs. Their system faithfully reproduces the natural structure of these vessels, and does so much faster than ever before. It can also transform these models into instructions that can be used directly by a 3D printer. The team has developed an algorithm capable of creating blood vessel networks very close to those of real organs. Integrated into their open-source SimVascular software, it uses simulations to ensure proper blood flow, prevents vessels from crossing each other and forms a closed circuit with a single entrance and exit, while greatly speeding up the creation process.

“It took about five hours to generate a computer model of a tree to vascularize a human heart. We were able to get to a density where any cell in the model would have been about 100 to 150 microns away from the nearest blood vessel, which is pretty good,” explains Zachary Sexton, postdoctoral researcher and co-first author of the study. The model included around a million vessels. “That task hadn’t been done before, and probably would have taken months with previous algorithms.” Although 3D printers cannot yet produce very fine networks, the researchers succeeded in printing a model with 500 branches. They also tested a simpler version using human kidney cells. Using a bioprinter, they circulated a nourishing liquid through 25 small vessels, keeping many of the cells close to the network alive.

Photo Credits: Freepik

Towards Functional Blood Vessels

The researchers point out that the structures created are not yet real blood vessels. They are simply 3D printed channels, without the specific cells that normally make up vascular walls. “This is the first step toward generating really complex vascular networks,” explains Dominic Rütsche, postdoctoral scholar and co-first author on the paper.

“We can print them at never-before-seen complexities, but they are not yet fully physiological vessels. We’re working on that.” The team is now working on making these networks fully functional. They are also looking for ways to encourage the finest vessels to form naturally, while improving the speed and precision of the bioprinters.

What do you think of the 3D printed blood vessels? Let us know in a comment below or on our LinkedIn and Facebook pages. Plus, sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel. Interested in more medical and dental 3D printing news? Visit our dedicated page HERE.

*Cover Photo Credits: Stanford University