Researchers create 3D printed artery to monitor blood pressure remotely

At the University of Wisconsin-Madison, scientists have developed 3D printed blood vessels that enable patients to monitor their blood pressure remotely. This is promising research given that today, when surgeons replace part of a blood vessel, the grafted vessel is monitored by CT scans, ultrasounds and other expensive imaging techniques. In the United-States alone, it’s 450,000 patients per year that undergo this operation to treat blood clots, coronary disease, stroke damage and other cardiac diseases. Moreover, between 40% and 50% of these grafts fail, which is why researchers are attempting to develop solutions to monitor blood pressure in order to initiate safer treatments early on.

At the University, it’s materials science engineers that successfully 3D printed the artificial blood vessel to allow doctors and patients to keep tabs on the patient’s health remotely. The implantable vessel was made of a composite material that is also flexible. Xudong Wang, and graduate student Jun Li that worked on this project published the study in the Advanced Functional Materials journal. Wang explains: “This artificial vessel can produce electric pulses based on pressure fluctuation which will be able to tell precisely the blood pressure in the vessel without using any additional power source. And because of the 3D geometry, the electric pulse profile will be able to tell if there is an irregular motion due to blockage inside in the very early stages.”

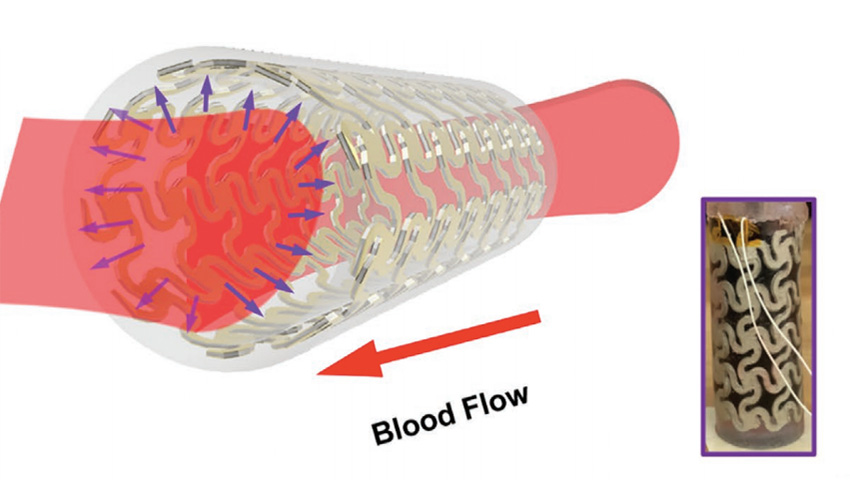

The 3D printed implantable blood vessel

Wang has researched materials for artery projects for a long time in previous research projects. He was especially interested in a material that would be flexible and piezoelectric, meaning that it is able to produce an electric charge from mechanical stress, as well as biocompatible. Therefore, the team combined sodium potassium niobite piezoceramic nanoparticles with a polyvinylidene fluoride polymer which is ferroelectric (able to flip polarity when an electric field is applied). They then 3D printed a tubular artery using the material and an off-the-shelf 3D printer. The printer extrudes the material through a strong electric field close to the nozzle to polarize the ceramic particles, giving the structure its piezoelectric property.

Then, came the testing stage. Graduate student Jun Li hooked the artificial artery up to an artificial heart system before simulating blockages, high blood pressure and other issues. The self-powered material was able to correctly detect changes in force and pressure within the artery. The researchers’ next step is to optimize the production of the new ferroelectric composite and the 3D printing process. The team also wants to find ways to make the 3D printed structure even more sensitive, and plans to collaborate with researchers in the biomedical field to test the artery with even more realistic models of the circulatory system.

On the left Xudong Wang and on the right Jun Li

Finally, while researchers are working on many other types of artificial blood vessels and organs, Wang thinks this technique has some advantages over more complicated techniques. “This is an easy, scalable technology,” he says. “Our new printable composite material allows us to make a 3D structure in one step that can show multi-functionality right out of manufacture.” You can find more information HERE.

What do you think of this project? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!