Scientists manage to 3D print transparent glass for the first time

Researchers at the Lawrence Livermore National Laboratory have successfully 3D-printed transparent glass. What’s more, this test was successfully conducted at room temperature. Reports from the test claim glass structures with composition gradients can also be produced with this method. This is a big deal: it was impossible previously using traditional manufacturing.

Glass: surprisingly useful?

Although dangerous in a bar fight, glass has some important uses in science. Its transparency, chemical/heat resistance and strength make it very attractive to scientists. Moreover, glass is used for many things in society like glasses (both kinds), cameras, mirrors and more. Therefore, the ability to print glass into custom shapes for testing is great news for scientists. Hopefully, this will lead to more successful experiments in the future that benefit our lives. In addition, being able to 3D-print glass with customisable properties will revolutionise opticians. Instead of the complicated process used currently to create glasses for your eyes, the perfect set could be made in front of you during your check-up.

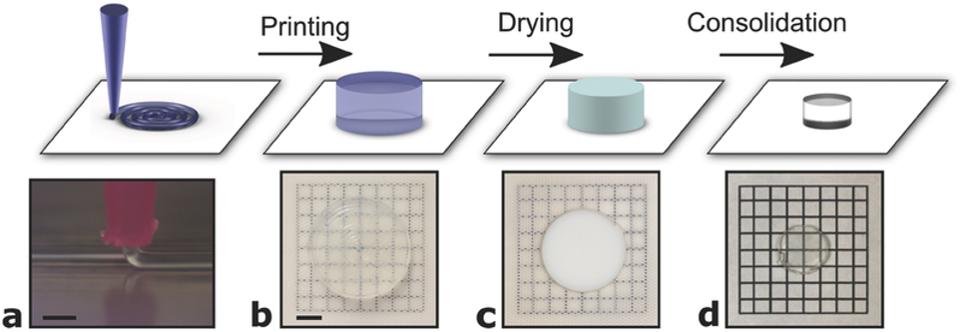

This breakthrough is important. Though not the first time glass has been 3D-printed, it is the first time it has been 3D-printed transparently. This new glass is finally superior to glass made by traditional methods, rather than previous, low-quality 3D-printed glass. The glass is created in two steps, it’s printed and then sintered. Firstly, the ink containing glass particles is printed into shape. The object is then heated until it becomes transparent, and after cooling there is no evidence that it has been printed at all. Then, the glass is polished and finished.

New, superior glass

Advantages of this ‘superior’ glass include the ability to customise the refractive index of the glass. This is better as glass with different levels of refraction can be included in one flat optic. Flat optics are superior as they can be easily polished. This may allow higher quality optics to produced in areas like glasses or within cameras. Moreover, the ability to produce more intricate shapes offers another variety of benefits. This is another exciting development in the 3D printing world, further showing its usefulness in almost every sector.

Are you a photographer or perhaps an optometrist, or just excited by these developments anyway? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!