ReJI Bioprinting Technology Accelerates Drug Development to Help Fight Cancer and Arthritis

Bioprinting has been used for medical purposes since around 2000. But, it has its limitations, particularly when it comes to drug development, where costs remain high. However now, thanks to financial support from Versus Arthritis, researchers at Newcastle University have developed a new method of 3D bioprinting gels containing cells, named ReJI, which could pave the way for advances in the development of treatments for cancer, heart disease and arthritis.

This process, which has capable of faithfully reproducing human tissue, has been patented in the USA and Europe. In addition, under the leadership of Professor Kenny Dalgarno, the team founded the startup Jetbio to attract investment for the worldwide deployment of the ReJI printer in laboratories.

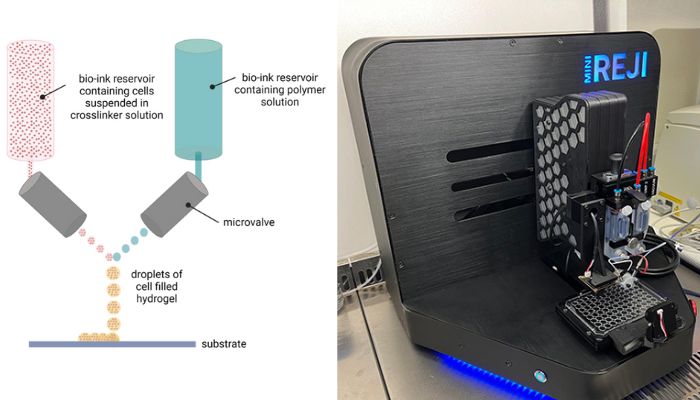

Left: 3D printing technology and right: the ReJI printer

But how exactly does the printing process work? Called Reactive Jet Impingement, the technology based on a bioprinting process in which two liquids are sprayed against each other. One contains a cross-linking solution with suspended cells, while the other is a polymer solution. Mixing the two in air forms a cell-enriched hydrogel, which can then be 3D printed on almost any surface. This process is far faster than conventional technologies, and achieves ten times the cell density. What’s more, the resulting tissues resemble human tissue samples.

Due to this, Reactive Jet Impingement (ReJI) technology is able to play an important role in drug development, particularly for in vitro cell culture tests, where cells are usually grown on a flat surface, i.e. outside the body, under artificial conditions. However, these traditional 2D models do not reflect the reality of the human body, where cells interact in a 3D environment. This is where ReJI technology comes in: by printing cells in a 3D matrix, it enables tissues to be better reproduced, making testing more accurate. This helps speed up the whole process.

In addition, the Jetbio method offers other advantages: it is more economical and makes drug development more accessible, enabling more people to obtain treatments. Thanks to these results, the Jetbio team has already been invited to the Chamber of Deputies to present this technology as well as show how it could be used to optimize drug production.

Discussing the need for ReJI, Professor Kenny Dalgarno, from the Faculty of Engineering at Newcastle University, highlighted the current challenges of drug development, “Drug discovery is a complicated and extremely costly process involving multiple rounds of testing before they reach clinical trials. In clinical investigations only one in ten of compounds tested proceeds to reach market. These rates of failure make it clear that we must improve our models so that they are more representative of drug response in humans. There is currently a lot of interest in developing better human in vitro models of diseases and tissues so we have better ways of testing drugs.”

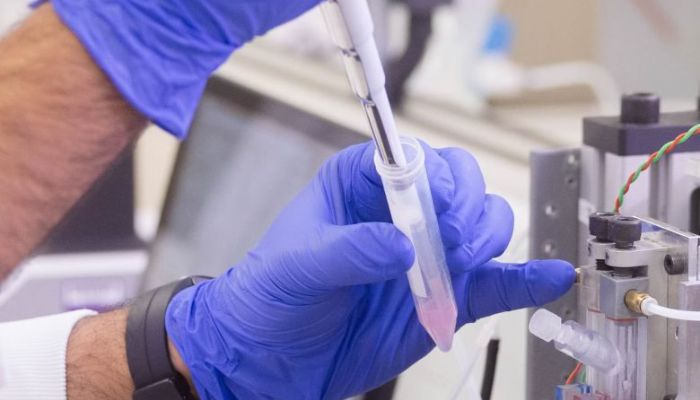

The Reactive Jet Impingement (ReJI) bioprinting technology is a rapid system for printing biomimetic gels for the development of in vitro disease models for drug testing

The scientists are also aiming to develop a technology for arthritis patients, enabling more personalized cell culture as part of the existing autologous chondrocyte implantation (ACI). “The JetBio team are in the vanguard of research driving forward new technologies that promise to improve both the quality and speed of drug development. These advances can potentially bring new drugs to the population sooner – and that applies to treatments for arthritis, cancer and cardiovascular disease. This is a very exciting leap forward,” confirms Lucy Donaldson, Director of Research at Versus Arthritis.

The printers are expected to be used in the future to treat a wide range of diseases, as in the EU-funded REBORN project. In this project, a team from Newcastle University is developing in vitro models of a heart ventricle. To find out more about the ReJI printer and Newcastle University, click HERE, and to discover Jetbio, click HERE.

Furthermore, in the video below, Professor Kenny Dalgarno, Jetbio’s Scientific Director, explains how the process is used for the evolutionary manufacture of in vitro leukemia models.

What do you think of the ReJI technology? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel. You can also find more news in the medical and dental sector HERE.

*All Photo Credits: Jetbio and Newcastle University