Startup of the Month: 3D MicroPrint

A well-known German company in the 3D printing industry is EOS. EOS have been in the 3D printing industry for more than 25 years, and pioneered laser sintering technologies. EOS recently cooperated with another company to create a new innovative startup in 2013, called 3D MicroPrint. When we heard of their fascinating new microlaser sintering technologies, we knew we had to interview them. Therefore, here is our interview with 3D MicroPrint about what they do, their goals for the future, and more!

3DN: Could you introduce the 3D MicroPrint in more detail?

CEO Joachim Göbner

The 3D MicroPrint GmbH was founded in 2013 in Chemnitz (Germany) as a result of a cooperation between the EOS GmbH and the 3D-Micromac AG. Our procedure Microlaser sintering (MLS) combines the two worlds of additive manufacturing and laser micro machining. As a 3D MicroPrint GmbH, we have taken this process to an industrial level and continue to develop the technology. We specialize in the development, manufacture and sale of MLS machines, as well as the production of micro-metal parts through micro laser sintering.

3DN: What is behind the ‘micro laser sintering’ technology, and how does it differ from other 3D printing technologies?

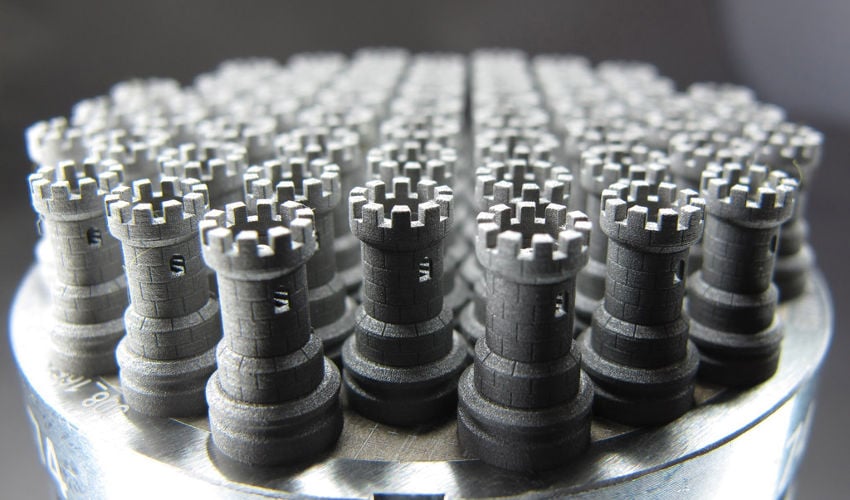

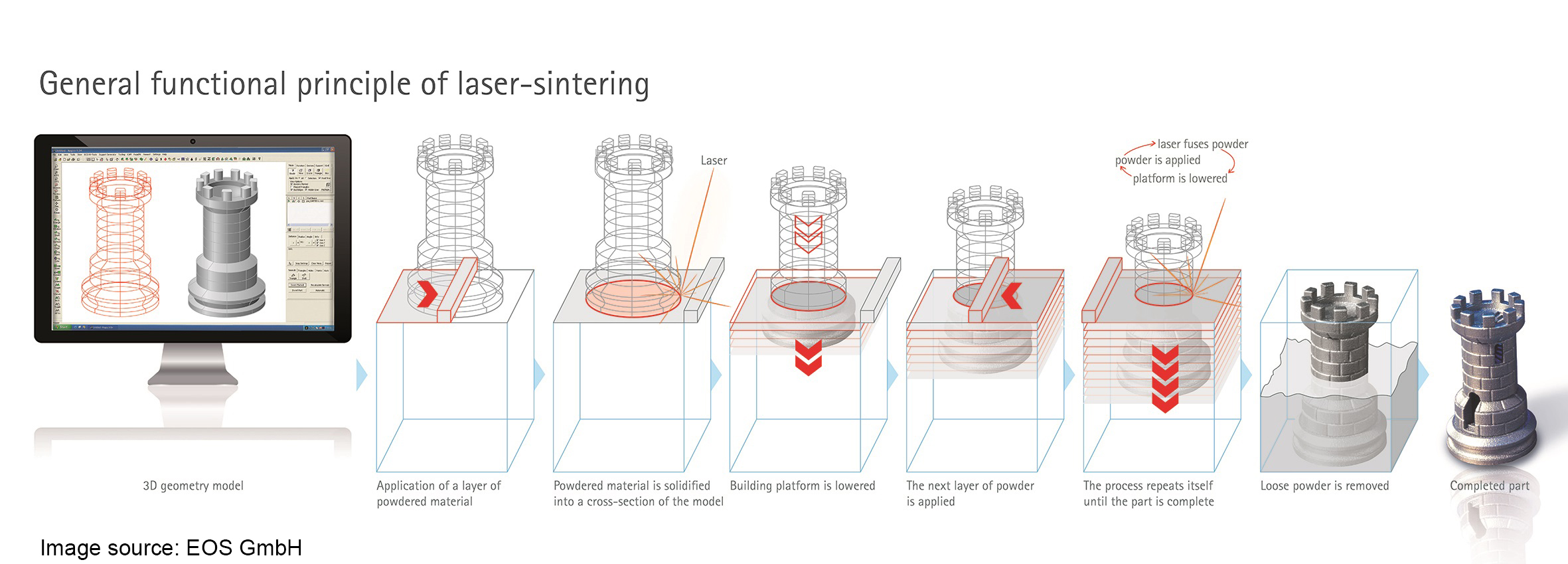

Microlaser sintering is a powder bed process in which the component is built up layer by layer. An infrared fiber laser is used to melt the powder, which is focused on a spot diameter smaller than 30 μm. The biggest difference to conventional additive manufacturing by means of laser sintering lies in the powder particle size used. The powder is smaller by a factor of 10 smaller than conventionally used powder sizes with a powder particle size less than or equal to 5 μm. As a result, a much finer resolution of the components can be achieved. Currently, this resolution is unique for metal components worldwide.

3DN: Which machines are currently working with this method? Which materials are used here?

The machines were designed by us and continuously developed. In 2013, the DMP50 GP was the first industrial grade MLS machine. Since 2016, the successor machine generation DMP6X is available, modular, user and service friendly and divided into three different variants. Currently 6 machines are in use worldwide. As materials different metals are used. Mainly we are currently processing the stainless steel 1.4404 (316L) and the medical stainless steel 17-4PH. Titan 6-4 is in pilot production. Furthermore, there have been successful trials with other metals, such as tungsten or molybdenum. The prerequisite is that the metals are available and processable in a very fine powder particle size.

The Micro Laser Sintering process.

3DN: To whom, or in which industries and for which applications is this process particularly suitable?

Our general principle is: We manufacture for all industries. If you are looking for an innovative production solution for your micro component, you should contact us immediately. Most customers currently come from the medical industry. We also have customers in the energy, aerospace and jewelry industries. Especially complex geometries are suitable for additive manufacturing. Such as nozzles with variable channel cross-sections, grid structures or movable assemblies. Otherwise, extraordinary geometries, in the production of which conventional micro-machining methods reach their limits.

A 3D printer capable of micro laser sintering.

3DN: What are the plans of 3D MicroPrint GmbH for this year?

The most important thing is the satisfaction of our customers. We achieve this through the high quality of components manufactured by means of microlaser sintering. That is why we are constantly working to improve the powders, our machines and the process parameters. In the current fiscal year, we invested in new processes for assessing powder quality and component quality. These methods have been integrated into the operational processes in order to be able to deliver consistently high quality to our customers. In addition, we are working on several projects to open up further sectors and make new materials available to the market.

3DN: Do you have any final words to our readers?

Many thanks to 3DNatives for their interest in 3D MicroPrint GmbH and our technology. Feel free to visit our website: http://www.3dmicroprint.com/ and if you have microcomponents that you would like to make additively – please send us an inquiry to: in**@**********nt.com.

What do you think about 3D MicroPrint? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!