3D Hubs helps Fillauer Composites create carbon-fiber prosthetic feet

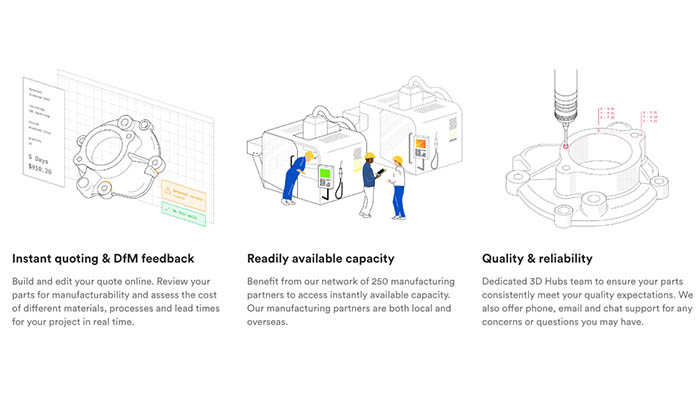

3D Hubs, based in the Netherlands, is a leading online manufacturing platform that leverages its global network of manufacturing partners to respond to customers’ production needs. More precisely, it provides industrial 3D printing, CNC machining, injection molding and sheet metal fabrication services. The company believes the future of manufacturing lies in distributed manufacturing, enabling engineers worldwide to create revolutionary products more quickly and efficiently, with the ultimate goal of accelerating innovation in every industry. One of the key benefits the 3D Hubs online manufacturing platform offers is its instant quoting system. Designed to deliver a frictionless user experience, the AI-driven platform bases its unit prices on several thousand data points.

Today, it’s obvious that 3D printing goes far beyond the individual maker. The number and range of industries using 3D printing as an industrial technology to produce both prototypes and end-parts is skyrocketing. Also, the relatively young technology can no longer be considered as purely a prototyping technology, even though it’s clear it will not replace traditional manufacturing methods for very large series production. Despite this, 3D printing is becoming mainstream – transforming our current production methods with its impacts on design, time-to-market, customization, supply chains and pricing. Multiple demanding sectors, such as automotive, aerospace, medical or advanced robotics are adopting this technology for industrial applications.

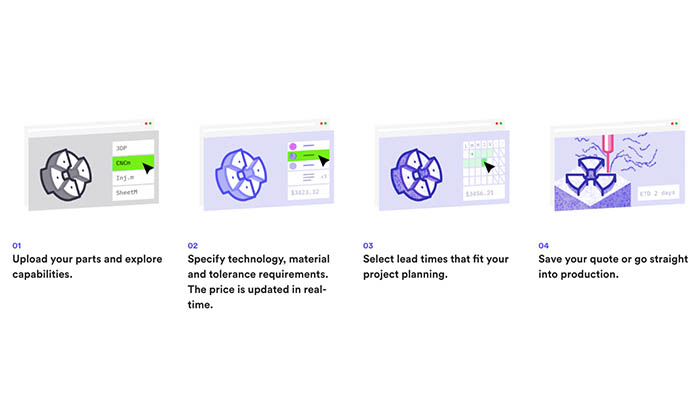

3DHubs’ platform explained in 4 steps | Credits: 3D Hubs

3D Hubs’ platform facilitates and accelerates production

The growing popularity of 3D printing is why 3D Hubs provides an intuitive online platform that facilitates production with various 3D printing technologies, in addition to other main manufacturing technologies such as CNC machining, injection molding and sheet metal fabrication. The platform allows users to upload a CAD file, define their necessary requirements, and then receive an immediate quote. The company also reviews and provides actionable feedback on the manufacturability of the part through its Design for Manufacturability tool. Once the part is uploaded, the order can be placed with the push of a button.

In the medical sector, 3D printing is advancing many applications and has generated numerous breakthroughs in the last few years. One of the key advantages of adopting additive manufacturing in this industry is the potential to customize medical devices. No patient is the same, which means a tailor-made solution is often necessary for their recovery or their day-to-day needs.

3D Hubs has a network of over 250 manufacturing partners | Credits: 3D Hubs

Fillauer Composites manufactures carbon-fiber-based prosthetic feet with 3D Hubs

Let’s look at the example of Fillauer Composites, orthotics and prosthetics manufacturer, leading in the evolution, design, and technology of prosthetic and orthotic products. It specifically designs carbon-fiber-based prosthetic feet for amputees. This means working with sensitive materials and tricky manufacturing processes. In order to develop these prosthetic feet, engineers at Fillauer Composites had to quickly get prototype parts and produce non-carbon fiber components in a way that was both cost-effective and didn’t burden the organization’s manufacturing department.

The manufacturer used 3D Hubs to get one-off, functional parts made from elastomer materials which their engineers could experiment with before producing the final carbon-fiber parts. As for production-level parts, they worked with 3D Hubs to manufacture brackets that help prosthetists attach the prosthetic foot to the amputee’s socket. To make this ABS bracket, injection molding was used.

The carbon-fiber-based prosthetic feet from Fillauer Composites | Credits: Fillauer Composites

Phil Thompson, design and manufacturing engineer at Fillauer Composites concludes: “For these plastic-based parts, working with 3D Hubs just took a lot of pressure off our manufacturing department. The 3D printing process really lends itself to making parts much more quickly and easily than a machining process. We’ve absolutely used 3D Hubs to prototype parts that would be impossible, or a nightmare, for us to machine in-house.”

3D Hubs provides access to several 3D printing technologies, including FDM, SLA, MJF, SLS, Polyjet and DMLS, for both functional prototypes and end-parts. You can find more information on 3D Hubs HERE.

What do you think of the 3D Hubs online manufacturing platform? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter to receive all of the latest news about 3D printing straight to your inbox!