3DExpress: Justin Bieber Launches Sneaker with Zellerfeld at SKYLRK’s Tokyo Pop-Up

Bieber Brings 3D Printing to Sneaker Culture

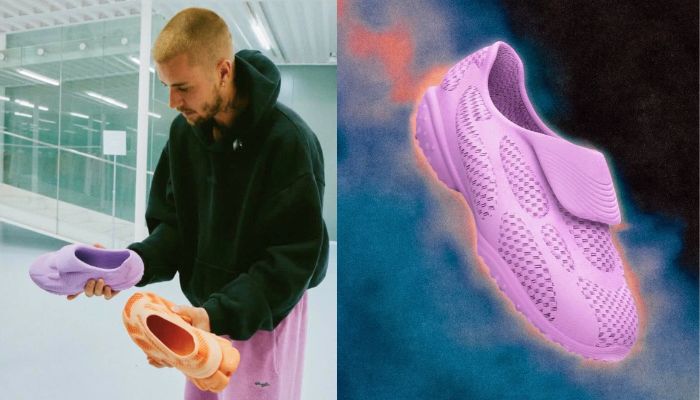

Additive manufacturing had its full pop-star moment this week as Justin Bieber debuted his first 3D-printed sneaker, the Earth Bender, created with Zellerfeld and launched at SKYLRK’s first-ever pop-up in Tokyo. The sculptural slip-on design features soccer-cleat-inspired forms and a mix of textures, including mesh-like side panels, all produced as one continuous 3D-printed piece. Zellerfeld will already be familiar to many readers as a footwear-focused 3D printing manufacturer and digital platform, helping designers transform experimental ideas into finished shoes, from independent studios to global brands like Nike and Havaianas. The Earth Bender is the latest project to emerge from that ecosystem, following Bieber’s launch of Skylrk with designer Neima Khaila earlier this year, putting additive manufacturing right at the heart of today’s sneaker culture.

(Photo Credit: (Right) Instagram via @lilbieber and (Left) Skylrk

LEGO Group to Deliver Keynote at AMUG 2026

You’ve likely seen the recent headlines about LEGO releasing its first retail set featuring a 3D printed part: a festive Christmas train. The timing is fitting, as the Additive Manufacturing Users Group (AMUG) has announced that Ronen Hadar, Senior Director and Head of Additive Design & Manufacturing at The LEGO Group, will be one of the keynote speakers at its 2026 conference.

The event will take place in Reno, Nevada, from March 15–19, with Hadar scheduled to speak on Thursday, the 19th. His keynote, “Additive Manufacturing at Scale in Consumer Goods: The Case of The LEGO Group,” will examine how the company is integrating 3D printing into an industry defined by high-volume, low-cost production. Hadar has spent more than 15 years shaping how one of the world’s most iconic toy brands uses additive manufacturing. His insights will offer attendees a detailed look at LEGO’s approach to innovation through AM. For more details on AMUG 2026, click here.

(Photo Credit: AMUG / Lego)

Saab Reveals World-First AI-Designed, Fully 3D-Printed Aircraft Fuselage

CurifyLabs Launches First 3D Printed Compounded Drugs for Pets

CurifyLabs has introduced a new 3D printing technology designed to bring personalized compounded medications into the veterinary space. The system centers on Curablend Vet, an excipient blend created specifically for printing pet-friendly doses, and works with the company’s automated Compounding System Solution, which produces soft, chewable gel pills in minutes. Because many drugs are not available in pet-specific strengths, pharmacists often rely on manual compounding steps that can be slow and inconsistent. CurifyLabs says its automated workflow replaces much of that variability by generating digitally documented, standardized 3D printed formulations tailored to each animal. The result is medication that is easier for pets to take, potentially improving compliance for owners. CurifyLabs CEO Charlotta Topelius calls the launch a first of its kind move for veterinary care, expanding a platform previously used only in human hospitals and pharmacies across Europe and the United States. Founded in 2021, the company says Curablend Vet marks a significant step toward modernizing compounding and bringing reliable, customized 3D printed medicine to the veterinary world.

(Photo Credit: Adobe Stock)

What do you think of Justin Bieber’s new 3D printing partnership with Skylrk? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.

*Cover Photo Credit: Skylrk