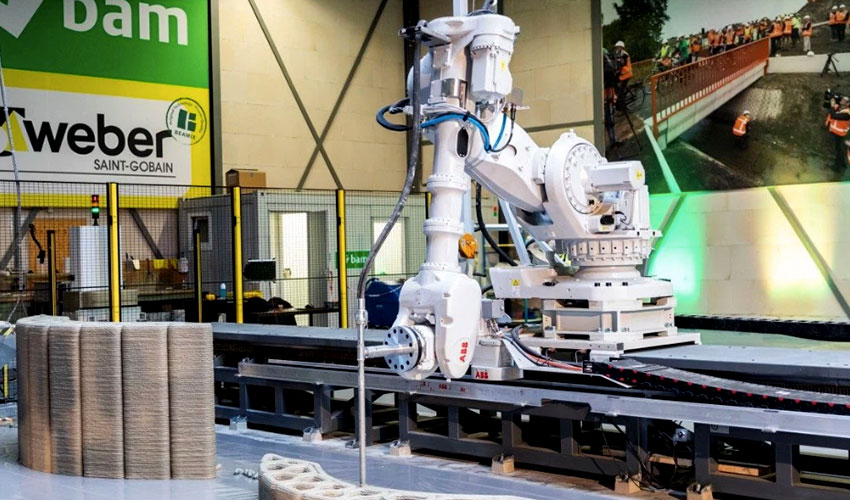

Europe’s First 3D Concrete Printing Facility

The first industrial 3D concrete printing facility in Europe was inaugurated on the 14th of January in Eindhoven, Holland. When applied to the construction sector, 3D printing offers many advantages whether in terms of costs, time or durability of materials. This is what Weber Beamix and BAM Infra will experiment with by 3D printing concrete elements for construction in this new facility. Indeed, their aim is to further develop this technology. The first order was announced the morning of the opening and will consist of the printing of four bicycle bridges for the province of North Holland.

As always, the advantages of the technology can be transposed to almost any sector. In this case, by printing concrete instead of using the usual casting methods, less material is needed. It is more cost-efficient as well as an environmentally friendlier way of producing (less CO2 emissions and waste).

“I think 3D printing of concrete has a fantastic future. For us, the ultimate goal is to be able to print a house on the construction site”, said Bas Huysmans, Managing Director of Weber Beamix.

3D Printing Houses

This facility will serve to 3D print houses in various chunks for the city of Eindhoven. “The first houses of Project Milestone will be printed in elements here and assembled on location. We hope that the last of the five houses can be printed on location, but that’s still very difficult”, said Marco Vonk of Weber Beamix. Why? “Here it is always 18 degrees and we have constant humidity, but outside you can’t control that. For example, if the temperature drops below 5 degrees, the concrete will not cure at all”, he added. Printing on location is always the ultimate goal.

Collaboration Between Different Parties

How did this collaboration come about? The Managing Director of Weber Beamix explains that he had always wanted to start printing in concrete but the market for it did not exist yet. It took about twenty years for a project to be initiated. “When twenty years later someone from Eindhoven University of Technology knocked on the door and wanted to start a project to print concrete, we were immediately enthusiastic”, explained Bas Huysmans.

BAM Infra and Beamix have always been involved in the research behind the technology from the start, establishing a middle ground between production and research. The aim is to have a healthy marriage between the university and construction industry.

Theo Salet, professor at the Eindhoven University of Technology adds, “There is still a lot of room for improvement. As you can see here, the speed of printing is far too slow, it should be ten times faster. There is also much to gain in the materials. We can think of different new types of concrete, for example in different colours, different reinforcement or lightweight variants”.

Want to know more about 3D Printing, we also interviewed Sika, specialist in concrete 3D Printing.

What do you think of prospect of 3D printed houses on site? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!