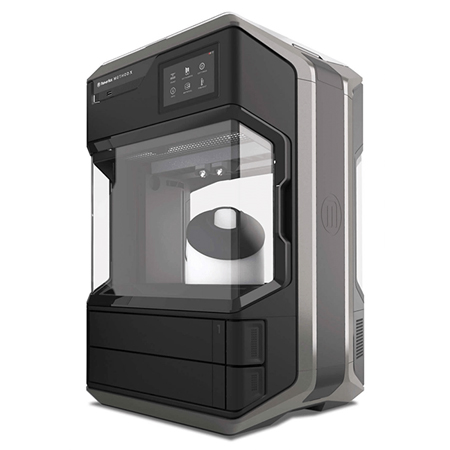

The Method 3D printer from the American company Makerbot is a revelation after years of absence from the brand, which was bought by Stratasys, one of the pioneers of additive manufacturing. Its development was based on several industrial technologies patented by the brand, approaches the trends of the industry and leaves behind the previous maker status of the company.

The Features of the Method 3D Printer

The machine is based on FDM technology and is aimed at a professional audience. With its dual extrusion and compatibility with a wide range of materials, the device has allowed the company to enter the field of industrial fused deposition printers. Its print volume is 15.2 x 19 x 19.6 cm when dual extruded or 19 x 19 x 19.6 cm when using a single extruder. Other features include layer resolution from 20 to 400 microns, a closed chamber and a color screen for easy operation.

Speeding Up Production Processes

The Method 3D printer allows users to accelerate their design and production processes. It is Makerbot’s first high-performance device and features an extremely stable metal structure that improves part accuracy. It bridges the gap between industrial and desktop 3D printers in terms of ease of use, price-performance ratio and dimensional accuracy. The MakerBot method differs from other desktop 3D printers with advanced features such as a heatable pressure chamber, soluble support material and more. Users also have the ability to control the printing process remotely to avoid part errors.