10 Reasons Why 3D Scanning Is Useful for 3D Printing

3D scanning is a non-contact, non-destructive process used to capture the shape and dimensions of real objects or environments. Utilizing lasers and cameras, this technology collects detailed data that can be transformed into high-precision 3D models for a variety of applications. Before exploring the specific uses where 3D scanning excels, let’s take a brief look at how the scanning process works.

The scanning process itself utilizes various technologies and devices, which we will delve into later in more detail. Regardless of the technology employed, the scan involves capturing data from multiple positions and angles to create a comprehensive model of the entire object. This data is then utilized by CAD technicians to generate 2D drawings or 3D models. These models serve numerous purposes such as analysis, design planning, inspection, archiving, or creating new objects—showcasing the diverse applications of 3D scanning. Let’s now explore why you should consider 3D scanning and the benefits it offers for 3D printing.

Photo Credits: Formlabs

#1: Versions for Every User

3D scanners are imaging devices that create a virtual 3D model of a real object by measuring it. The devices use various technologies. The scanning process can be carried out using laser scanners, structured light scanning or photogrammetry, for example. Laser scanners usually use LiDAR technology (Light Detection and Ranging), which emits pulsed light waves that are reflected by the objects to be scanned. Software classifies the data obtained and 3D models are created using the resulting data point clouds.

When scanning with structured light, the scanner emits the object to be scanned in a calibrated light pattern. When this pattern hits objects, it is distorted, allowing the contours of the object to be captured. In photogrammetry, the object is captured, measured and interpreted using photographic images. Depending on the requirements and application, 3D scanners are not only available with different technologies, but also in different designs. These can be portable handheld scanners, desktop scanners, scanners for large-format objects, or even scanner apps for smartphones. The market is so extensive that both hobby makers and professional users get their money’s worth, as 3D scanning can be used for smaller projects on the one hand and integrated into larger production processes such as the AM workflow on the other.

Photo Credits: Sculpteo

#2: Accuracy

3D scanning enables the precise and comprehensive capture of data. This data has more depth than words or sketches to represent an object. Generally, this data is accurate, but can vary depending on the calibration of the scanner and the technology used. By scanning from different positions, comprehensive data on shape, hidden features and fine details can also be collected. This helps to obtain accurate point cloud data that can be used to create a precise model for analysis, (re)design, and visualization. Although the data collection is very accurate, users and CAD engineers need to check the data model. This is particularly important if a new object is to be manufactured using the data obtained and the 3D model is to be used for subsequent 3D printing, for example, as this can prevent errors.

#3: Efficiency

Furthermore, these factors contribute to an efficient scanning process and rapid data acquisition. Unlike conventional measuring technologies that rely on coordinate measuring machines or hand tools, 3D scanning is significantly less tedious and time-consuming. In fact, a wealth of information can be gathered swiftly. For instance, a single powerful laser scan can capture millions of 3D data points in mere seconds. Since all necessary data can be acquired in the initial scan, there’s no need for additional site visits. This accelerated data collection process facilitates prompt creation of 3D models, thereby expediting project timelines and decision-making processes.

Photo Credits: 3DSpace

#4: Cost Efficiency

Time is money, which leads us directly to the next point: cost efficiency. The measurement itself requires fewer iterations and therefore less time and labor. This also makes 3D scanning a cost-effective alternative to other measurement technologies, nicely complementing 3D printing. This is a major advantage, especially when the scan is embedded in a costly production workflow, such as industrial additive manufacturing.

The high accuracy of the scanner mentioned above plays a crucial role in reducing errors, conflicts, and rework during the design or construction phases right from the outset, thereby saving valuable time and costs. While it’s true that professional-grade scanning devices come with a significant upfront purchase cost, the investment pays off through improved efficiency and reduced expenses in the long run. Moreover, there’s a wide range of scanners available in various designs and price points, including more affordable options and even free scanner apps that are popular among architects, interior designers, and makers. Overall, operating 3D scanners is intuitive, requiring minimal training, which further enhances their accessibility and usability across different applications.

#5: Security

With 3D scanning, data is captured through the scanning process without direct contact with the object. This has several advantages. Firstly, valuable artifacts that are scanned for archiving purposes or for repair or replication can be protected. Secondly, it also contributes to the safety of workers, as tripods can be used to capture remote, difficult to access or even dangerous environments with the scanner. This applies, for example, to surveying chemical or nuclear plants or areas with unstable ground.

Photo Credits: Multiviste/Hexagon

#6: Quality Control

3D scanning can be used in numerous situations to check the quality of components. Even during the production and prototyping phase, portable 3D scanners help to identify the causes of problems in the design. 3D scanning is also particularly helpful in recording the current status of a component that has already been used. This allows the actual state of a part to be determined, which is then compared with the target state – the model. The parts can then be serviced accordingly to ensure quality. If a part has been modified and adapted in the workshop, these changes can simply be recorded by scanning.

#7: Digital models

3D scanning spans a wide array of applications beyond any single field. It proves invaluable for documentation purposes, enabling digital models to be archived and preserved. This archival data serves as a foundational resource for ongoing projects or for historical preservation, particularly beneficial for museums and art institutions safeguarding artifacts and valuable artworks. Moreover, the scanned data facilitates object reproduction. Increasingly, industrial sectors utilize digital twins for on-demand access, integrating them seamlessly with 3D printing to achieve sustainability objectives through localized production. Additionally, scan data supports reverse engineering efforts, providing a detailed understanding of component functions for precise replication or modification.

Photo Credits: Creaform3D

#8: Personalizability

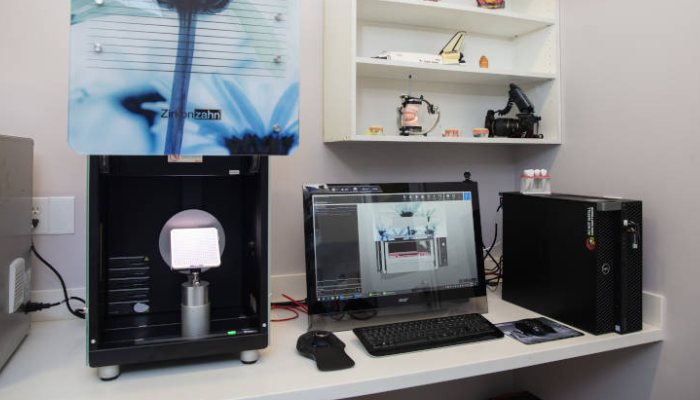

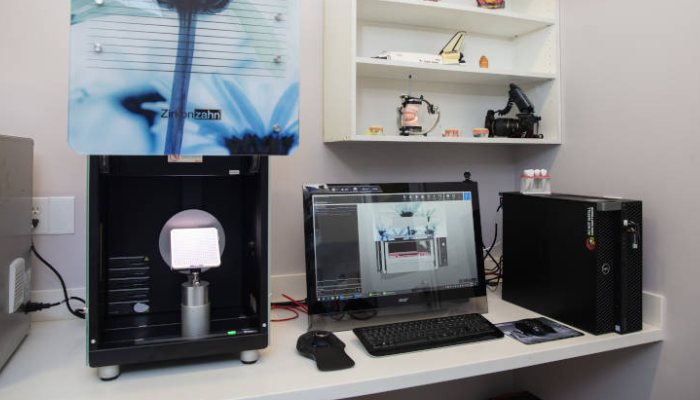

In the field of medicine and consumer goods, 3D scan data offers the possibility of personalization. Using body scans, a person’s individual measurements can be recorded, and medical products can be manufactured according to personal requirements, such as orthoses, prostheses, shoes, and insoles. Another area that should be explicitly highlighted is dentistry, which strives to offer customized implants and solutions. Many dental practices are already working with 3D printers to achieve this. However, this requires precise data that can be captured by scanners. This has resulted in a separate segment of dental scanners, where we find intraoral scanners and laboratory scanners. The combination of 3D scanning and 3D printing enables dentists to quickly generate custom-fit medical solutions.

The principle of customization is also becoming increasingly important in the consumer goods sector in order to win new customers or stand out from the market. The trend towards personalized consumer goods is fueled by technologies such as 3D printing. Together with 3D scanning, this allows customized products to be created efficiently. These are just a few examples of how and where 3D scanning technology can be used – the list of applications is long!

Photo Credits: Digital Dental Lab

#9: Improved Conception Phase and Product Development

3D scans serve multiple purposes beyond archiving and reproduction. They also provide a valuable starting point for new projects. During the design phase, scan data accelerates concept creation and reduces prototype design cycles. This efficiency often leads to fewer prototypes being produced or none at all, minimizing waste and promoting sustainability in both production and design. Digitized objects foster innovation in product development, mitigate costly errors, and expedite time to market. When integrated with 3D printing, these processes are further optimized, leveraging the sustainable and rapid prototyping capabilities of additive manufacturing.

#10: Compatibility with Other Technologies

Lastly, 3D scanning excels in its seamless integration with other technologies. While its primary function is data generation, this data can be effortlessly incorporated into platforms like CAD or BIM, serving as a launchpad for new projects. AR/VR technologies, which are increasingly reliant on scan data, are widely embraced in the entertainment, gaming, and tourism industries for immersive experiences. Moreover, scan data plays a pivotal role in production workflows, particularly in additive manufacturing, offering significant advantages in time, cost, accuracy, and versatility across various applications. 3D scanning typically initiates workflows, yet it’s essential to note that it can be effectively integrated rather than viewed as an isolated technology.

Photo Credits: 3Dprintjunction

Do you already have experience with using 3D scanning for 3D printing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Skywell