10 Reasons Why 3D Printing Can Improve Automotive Safety

In 2023 alone, motor vehicle crashes claimed the lives of 40,901 people in the United States, according to the U.S. Department of Transportation’s Fatality Analysis Reporting System. While many factors influence whether a crash is fatal—such as whether passengers are wearing seatbelts—this sobering statistic underscores the vital importance of advancing automotive safety. From the structure of the car itself to life-saving features like seatbelts and airbags, every detail contributes to minimizing harm and saving lives. But safety isn’t limited to crash response alone; it also includes how well a vehicle functions in everyday use. In this regard, 3D printing offers major advantages, helping manufacturers create vehicles that are not only more crash-resilient but also more ergonomic, accessible, and reliable. As automakers continue to push the boundaries of what’s possible, 3D printing has proven to be a transformative technology in the pursuit of safer, smarter vehicles. Here, we’ll explore ten key ways it’s improving automotive safety.

1. Accelerated Access to Repairs and Legacy Parts

One of the most immediate safety benefits of 3D printing lies in its ability to streamline access to critical vehicle components, especially during repairs. For older vehicles or those operating in remote locations, finding replacement parts can be time-consuming or even impossible. 3D printing allows for rapid, on-demand fabrication of legacy parts that might otherwise be discontinued, ensuring vehicles remain structurally sound and fully operational. This ability to maintain or restore a vehicle’s safety features without delay can be crucial in preventing further accidents and ensuring reliability on the road.

A replica carburetor created for a vintage racecar by Tecron (Image credit: Markforged)

2. Faster Prototyping for Safer Vehicle Designs

Speed is a critical advantage of 3D printing in the design and development phase of automotive safety. Traditional prototyping processes can be time-intensive, limiting the number of design iterations that can be tested. With 3D printing, engineers can quickly produce and evaluate multiple versions of safety-critical components, from crash structures to restraint systems. This iterative capability leads to more refined, thoroughly tested designs that are optimized for real-world performance. In the end, the ability to prototype rapidly means safer vehicles are brought to market faster.

3. Improve Accessibility for Drivers and Passengers

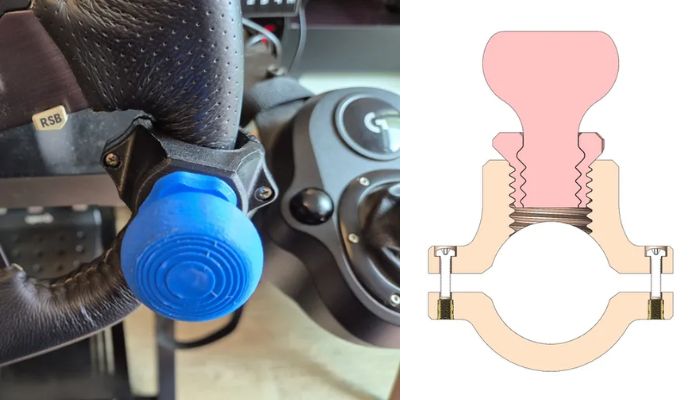

3D printing is also advancing safety by supporting more inclusive and adaptable vehicle designs. Users have created customized assistive devices such as steering wheel assist tools and entry aids, but there’s potential for so many more applications. These make vehicles more accessible but also safer, ensuring that all occupants can enter, exit, and operate the vehicle with confidence and stability. By reducing physical strain and improving ergonomics, 3D printed adaptations directly contribute to reducing injury risks for drivers and passengers with specific needs.

An assistive steering wheel knob is available to download on Cults. (Image credits: MIGUEPPC via Cults)

4. Structural Safety Through 3D Printed Seat Frames

When it comes to passenger protection, seat frames play a role in absorbing impact and maintaining posture during a crash. Many companies, including Mercedes, Audi and Porsche, have 3D printed them. 3D printing enables the creation of seat frames that are lightweight and engineered with advanced geometries that enhance energy absorption and strength. Customization based on occupant body types and seating positions can further improve safety outcomes. These tailored, high-performance components can reduce the risk of serious injury by providing consistent support and deformation resistance during a collision.

5. Enhanced Airbag Deployment with 3D Printed Housings

Another critical safety feature benefiting from 3D printing is the airbag system—specifically, the housing units that enable timely deployment. For instance, Joyson Safety Systems, a leading provider of mobility safety components, 3D printed Driver Air Bag (DAB) Housings using SLS technology. These DABs have to withstand high loads in addition to holding the inflator and the airbag cushion in place. With 3D printing, the designers could use a high-performance composite material, better controlling deployment mechanics, ultimately offering more comprehensive protection in the event of a crash.

A 3D printed airbag housing (Image credit: Joyson Safety Systems)

6. Head Padding for Whiplash & Impact Prevention

3D printed head-impact padding uses custom lattice structures that absorb and dissipate crash energy more effectively than traditional foam, reducing forces to the neck and head. These structures can be tailored to each passenger’s anatomy for better support and minimized gaps. When combined with properly positioned head restraints, they help prevent excessive head motion and reduce whiplash risk. While more research still needs to be conducted, early preliminary data from physics journals suggest that gyroids (a type of infill pattern) and reinforced gyroids have excellent compressive behavior suited for high energy absorption, in some cases lowering injury risk by up to 35%.

7. AM Battery Shields: Enhancing EV Safety and Efficiency

3D printed protectors for EV batteries improve safety by offering lightweight, high-strength structures that absorb crash energy and shield cells from impact or road debris. Advanced lattice and metamaterial designs outperform traditional materials in energy dissipation and weight reduction. Automakers like Volkswagen have cut battery housing weight by 60% using 3D-printed composites, enhancing both safety and efficiency. These designs also allow for integrated cooling and thermal protection.

8. Safer Automotive Lighting and Signaling

3D printing improves automotive safety in lighting by enabling rapid prototyping and customization of components like headlights, taillights, and signaling accessories. It allows precise testing of optical performance and durability, improving visibility and reducing glare in various conditions. Manufacturers like Ford use 3D printed lenses and housings for better fit, faster repairs, and reduced waste; all while maintaining lighting system integrity.

3D printed OEM turn signals on a Mazda Rx-7 (Image Credit: Michael Burton)

9. Lattice Structures for Enhanced Rollover Protection

3D printing boosts rollover safety by enabling lightweight, high-strength structures like crash rails, roof reinforcements, and roll cages. These components can be optimized to absorb impact and maintain cabin integrity during rollovers. Automakers use 3D-printed metal nodes and crash components to create stiffer, more resilient frames without added weight. This improves passenger protection while enhancing vehicle efficiency. Early data from Yanshan University suggests that lattice‑reinforced roof pillars and crash boxes can redistribute and absorb impact forces during roll‑over, reducing intrusion and deformation by offering up to 43 % more energy absorption

10. Honey-Comb Crash Energy Absorbers & Impact Zones

3D printed underbody shields with built-in impact zones help protect key components like fuel systems by deforming in controlled ways during collisions or debris strikes. Tuned crash energy absorbers like lattice or honeycomb structures efficiently absorb and dissipate energy, often outperforming traditional foam or hollow parts. Designs can include crush initiators and multi-material layers to further enhance impact resistance. These solutions offer lightweight, customizable protection with improved crash performance. A recent study in the Journal of Materials Engineering and Performance found that honeycomb micro-lattice exhibited up to 47% higher compressive residual stress than traditional armor steels, enhancing its energy absorption. Furthermore, it found that these 3D printed materials were more corrosion resistant by up to 57%.

![[Right] A Singaporian 3D printed car utilizing honeycomb structures. (Credit: NTU) [Left] A cross-section design using the application of a 3D printed honeycomb structure (Credit: Aamer Nazir)](https://www.3dnatives.com/en/wp-content/uploads/sites/2/2025/08/10rescar-photos-1.png)

[Right] A Singaporean 3D printed car utilizing honeycomb structures [Left] A cross-section design using the application of a 3D printed honeycomb structure (Credit: Aamer Nazir)

*Cover Image Credits: Adobe Stock (left) and Tyler Clemmensen via Unsplash (right)