10 Reasons to Adopt 3D Printing

Today, many companies in the manufacturing industry still use traditional production methods. That being said, what is known as the fourth industrial revolution is becoming more and more of a reality, leading to the adoption of new methods of creation and manufacturing. These innovative advances in Industry 4.0 include artificial intelligence, virtual and augmented reality, big data and 3D printing. The latter has had a significant impact on the manufacturing processes of many industries, and is set for much greater growth in the coming years. To ensure that these organizations aren’t left behind and can make the leap into new technologies, and additive manufacturing in particular, we’re bringing you a new editorial format today. In this article, we’ve listed no fewer than 10 reasons why a user or company should consider adopting 3D printing into their business.

#1: Waste reduction

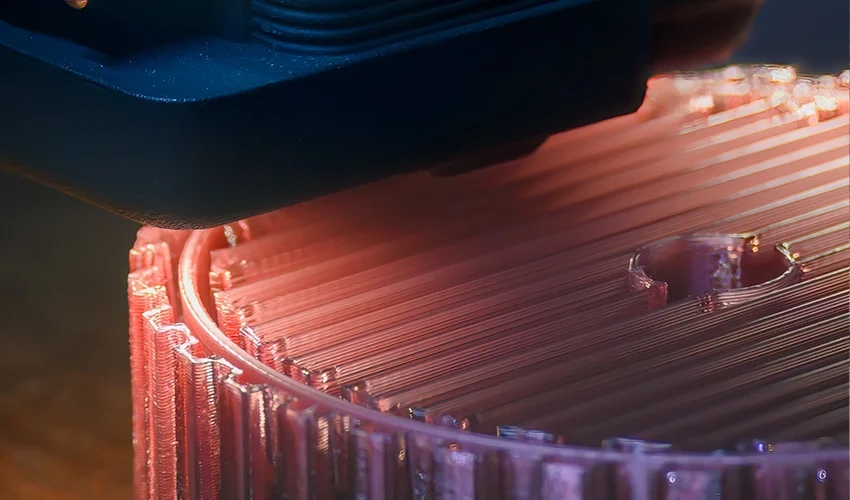

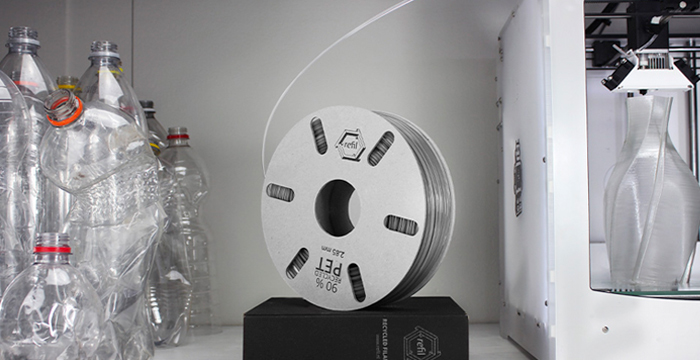

Additive manufacturing, as the name suggests, produces a part by adding material, layer by layer. It therefore uses only the material required. Unlike subtractive production methods, which waste large quantities of raw materials, the use of 3D printing significantly reduces waste. This is good for the environment, because no materials are thrown away unnecessarily. And if we go a step further, in powder-bed processes, unsintered or fused materials can be reused in future prints, provided they are mixed with new powder (depending on the technology, the recycling rate will be higher or lower). Additionally, Plastic objects can often be recycled into 3D-printable filaments or granules to create new parts. This is a key reason for many industrials to adopt 3D printing into their activities.

3D printing is characterized by the fact that only the material required to create the parts is used

#2: A Wide Variety of Technologies and Materials

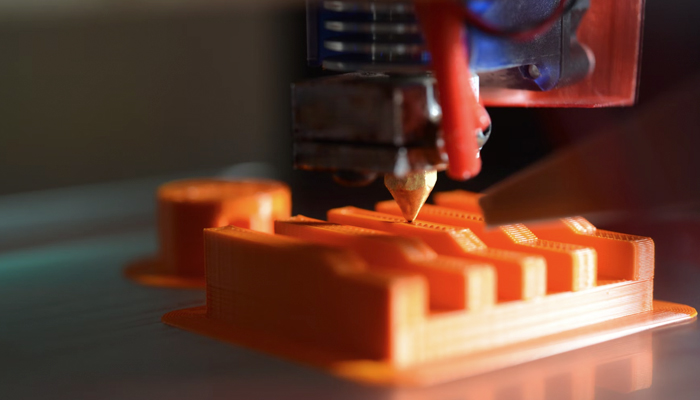

The world of additive manufacturing is vast when it comes to technologies and compatible materials. There are seven families of 3D printing technologies, encompassing many different methods. From extrusion processes to resin, powder bed or material jet systems. There is also a wide range of materials compatible with these technologies. The most common are polymers, metals and ceramics, among others. However, the versatility of 3D printing means that structures can be created using truly astonishing materials, such as concrete, food, wood or even stem cells.

#3: Freedom of Design

Another reason to adopt 3D printing is its design flexibility. This process enables the creation of parts with complex shapes that would be impossible with other production systems, or at least not under the same conditions. With some technologies, this is made possible by the use of print supports. Other systems, such as those based on a powder bed, use the powder itself as a support. You may have heard of the acronym DfAM or Design for Additive Manufacturing, which stands for the set of tools available to create 3D printable models, whatever their complexity. All these factors make it possible to create unique parts, with precise details and surprising geometries – some even with internal cavities – in a single process, without the need for assembly.

#4: Customization

Related to the previous point, additive manufacturing offers a multitude of customization options, including mass customization. A highly versatile technology, it enables users to adapt standard designs or models to their own tastes. One sector that benefits greatly from this aspect is consumer goods, where the consumer participates in the creation of the final object according to his or her preferences. This aspect is also important in the medical field, where 3D printing is increasingly used, whether for the manufacture of pharmaceutical products or medical devices made to perfectly fit the patient’s anatomy.

Customization is another reason to use 3D printing (photo credits: Invent Medical)

#5: Cost-Effectiveness

When it comes to investing in a 3D printer, many companies are primarily interested in costs, profitability and return on investment (ROI). This involves a series of cost calculations to find out how much you can save by investing in a 3D printer. We can also calculate the number of parts and, consequently, the amortization period of the initial investment. On the other hand, when you need to create a unique model, such as a spare part, using 3D printing through a manufacturing service is also a cost-effective option. By outsourcing this service, you pay a single price for the part, which is usually not very high. This makes it an attractive technology for prototyping and small series production.

#6: Rapid Production

3D printing may not be the fastest manufacturing method, but it can considerably shorten production times, another significant reason why a user may choose to adopt one or more of the technologies. The speed of the process itself depends on many factors, such as the technology used, the post-processing required, the parameters set or the complexity of the design, among others. Nevertheless, it’s a method that favors local, centralized manufacturing, so there’s no need to create parts elsewhere and then ship them out. This translates into a shorter lead time from the moment the part is designed to the moment the user receives it.

#7: Strong, Lightweight parts

Certain materials compatible with 3D printing can be used to create high-performance parts for the most demanding industries. If they are also reinforced with fibers, much greater strength and robustness can be achieved. When these materials are combined with topological optimization or generative design tools, it is possible to obtain lighter parts without affecting the characteristics of the model. Thanks to such software, it is possible to identify the most important areas of a model and reduce all those that do not affect its basic structure. In this way, the mechanical properties of the part are maintained, but with less material.

Many 3D printing materials offer a high strength-to-weight ratio. The use of design tools can also enhance this aspect

#8: Entry Price/Accessibility

The range of different technologies mentioned above means that the price of entry varies considerably. Clearly, the most advanced professional manufacturing systems, and the use of materials such as metals or high-performance polymers, tend to be very expensive. However, for those new to the technology, price need not be a constraint. Some FDM and resin 3D printers are available today for less than $200, and this price can be even lower if the machine is delivered as a DIY kit. Moreover, as mentioned above, many 3D printing services are available for those who are not yet ready to invest in their own equipment and wish to enjoy the benefits of additive manufacturing.

#9: Prototyping/Rapid Iterations

Although it is now used more to create end-use parts, additive manufacturing was first used primarily for rapid prototyping. It’s a method that cuts lead times by producing prototypes in-house. What’s more, it enables multiple iterations of the same part to be created, in order to find the right design, functionality and so on. This is particularly useful in a product development phase.

#10: On-Demand 3D Printing

As mentioned above, access to the technology can be gained by purchasing a machine or through a 3D printing service. In both cases, on-demand manufacturing is a key point to emphasize, as it allows you to obtain only the parts or models you need, freeing you from storage issues. You simply have your digital 3D model and send it to the printer when you need it. This in turn encourages local manufacturing, reducing lead times and promoting a more sustainable production model.

Photo Credits: Fiverr

What do you think of our reason to adopt 3D printing? Would you integrate it into your business? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.