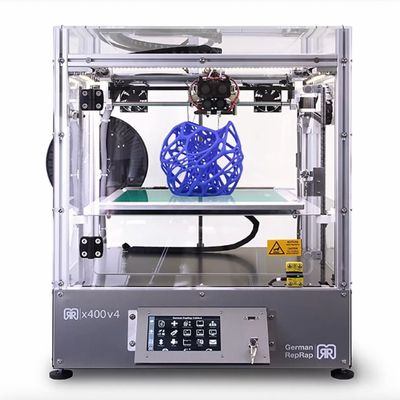

The x400 is a 3D printer which uses Fused Filament Fabrication (FFF) from the German manufacturer innovatiQ, based in Bavaria. It is part of a wide-ranging portfolio of the 3D printing manufacturer, which also includes the TiQ 5, LiQ 320, x500eco, x1000 and MiQ 5 machines. The x400 is a 3D printer that delivers industry standard pieces. Due to its installation space of 350 x 400 x 310 mm, it is mainly used for customization in development and prototypes. The machine, which was developed and manufactured in Germany, has a professional ventilation system that ensures uniform temperature regulation within the installation space and thus also positively supports process reliability. In addition, there is also an extruder ventilation system that ensures an optimal temperature at the extruder, thus reducing the risk of print issues associated with sub-optimum temperatures.

Features of the x400 3D Printer

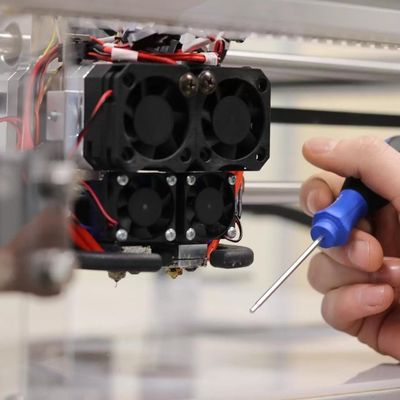

As a user of the x400, you can rely on the material supply via the filament tracking system, as it automatically detects when the filament is nearing its end and consequently pauses the print job in the process. You should also know that the print head is equipped with DD3 Dual Extruder technology. Specifically, this means that it is an extruder with two different nozzles that can be used – depending on the application and selected material. Just like the Full-Metal-Hotend, the DD3 extruder is easy to operate and additional readjustment of the print head is not necessary, making it a hassle-free user experience.

Weighing just 50 kg and measuring 735 x 730 x 777 mm, the x400 3D printer also supports the user on the basis of its automatic print bed leveling. The print bed is levelled in height and therefore only needs to be calibrated once, which saves the user a great deal of time.