The VX4000 3D printer comes from the German 3D printing manufacturer voxeljet, which has specialized in the production of industrial machines for years. Besides the VX4000, their portfolio also includes printers such as the VX200, VX200 HSS, VX1300 X and the VX2000, all of which are designed for professional use. The VX4000 3D printer, which was introduced to the market in 2015, is a printer that uses binder jetting technology, with sand as the material. With its maximum build volume of 8000 liters, it even allows users to produce parts up to 4000 mm in length, while achieving a resolution of up to 200 dpi. Furthermore, the bidirectional print head allows the user to print the entire construction field in just two passes.

Details of the VX4000 3D printer

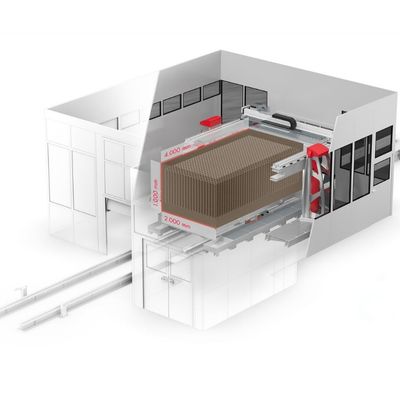

Equipped with a build envelope of 4000 x 2000 x 1000 mm, this machine is primarily suited for small batch and series production, though the manufacturer also cites prototyping as a possible application for the 3D printer. Like the entire VX series of 3D printers from voxeljet, this machine also has a well thought-out ergonomic concept, which leads to a high level of user-friendliness, as well as high productivity, which can be attributed to the great reliability in terms of industrial multi-shift operation. According to the manufacturer, the VX4000 is one of the most ‘economical and productive’ printing systems in the world.

As a user, you can also enjoy economic benefits from this machine, such as reduced development and production time when it comes to design and function. Also in terms of geometric freedom, you can face manufacturing limitations and thus produce more easily and efficiently.

The printer uses furan resin (thermosetting resins derived from waste vegetable matter), which are optimized for 3D printing and standardized quartz sand/silica. It can therefore be integrated seamlessly into existing value chains at small or larger volumes.