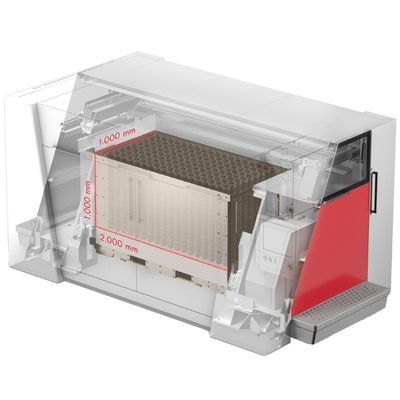

Behind voxeljet is a German company that has been dedicated to the production of 3D printing solutions for over 20 years. With a focus on the production of industrial machines, the portfolio includes 3D printers such as the VX200, VX200 HSS, VX1000 or the VX1300 X – but also the VX2000. This 3D printer is a machine that is considered particularly efficient, as it has a build volume of 2000 liters. Another reason why this machine is considered highly efficient is the fact that it is a combination of bidirectional printing technology as well as simultaneous powder application. In concrete terms, this means that this machine, which uses binder jetting technology, prints the entire build area extremely quickly – in just two passes per shift. At the same time, the user also benefits from a resolution of up to 300 dpi and a size of 1000 x 2000 x 1000 mm.

Features of the VX2000

When it comes to the possibilities of the VX2000, the user has a whole range. Starting with the binders, where both furan and phenolic resin binders can be used. This has an impact on the compatibility for 3D printing for sand molds or dies in a wide variety of sands. These sands can vary: whether a standard quartz sand or even specialty sands such as chromite or cerabeads, for example, the VX2000 shines with its material friendliness. The manufacturer states that the use of this 3D printer is mainly suitable for prototyping as well as for small series, but should you aim for series production, this is also possible with the VX2000. It is also important to mention that this machine can process up to 92 L/hour, which makes it an extremely economical and productive 3D printing system, as well as the high ease of use that accompanies the user thanks to the well thought-out ergonomic concept.