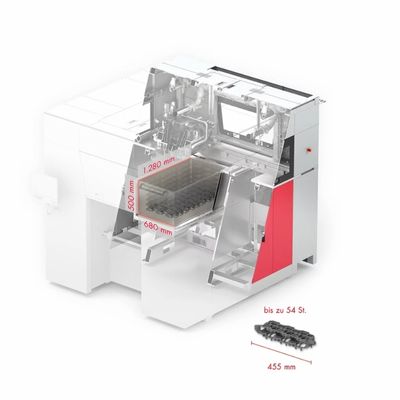

The supplier of the VX1300 X 3D printer is voxeljet, a German company that holds around 20 years of experience in the field of 3D solutions. They focus on the production of machines designed for the industry, in which the VX1300 X joins the portfolio next to machines such as the VX200, VX200 HSS, VX1000 or VX1000 HSS. In the case of the VX1300 X, it is a 3D printer that is intended for mass additive manufacturing, according to the manufacturer. Especially when it comes to machine productivity, the VX1300 X stands out, especially since it has been designed to be intelligent as well as low-maintenance and can also be easily integrated into existing Industry 4.0 networked production environments. The machine uses the binder jetting process and, in addition to series production, is also suitable for small batches and prototyping. The size of the printer is 1280 x 680 x 500 mm.

Details and features of the VX1300 X 3D printer

This machine enables its user to achieve maximum productivity, not least due to its output of 179L/hour, as well as a high level of user-friendliness, as this 3D printer, like the entire voxeljet VX series, also features an ergonomic well thought-out concept. However, the machine, designed for continuous use, is not only designed for industrial multi-shift operation, because voxeljet has also paid strong attention to the sustainability factor, especially here, because this is compatible with inorganic binders, which is beneficial for both people and the environment. With a resolution of up to 300 dpi, the Vx1300 X offers consistently high-quality results. The 3D printer from voxeljet uses sand as the material, with a water glass-based process (IOB), making it perfect for the high standards of the foundry industry. The sand type used is classical quartz sand (also known as silica sand, or industrial sand) with different grain sizes.