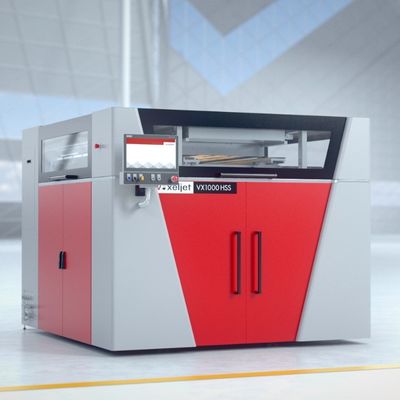

The German company voxeljet, which is based in Friedberg, has over 20 years of experience in the field of 3D solutions. With a focus on the production of industrial 3D printers, the VX1000 HSS has established itself on the market for additive manufacturing solutions, alongside the VX200, the VX200 HSS, the VX1000 and the VX1300 X. The VX1000 HSS, which was introduced to the market in 2021, is the first 3D printer from voxeljet. This 3D printer, which was introduced to the market in 2021, uses the polymer high-speed sintering process and is compatible with thermoplastics such as PA12, PP, TPU and others. One point of attention here is the enormous flexibility in the course of using different materials, as they can be replaced within a very short time, which leads to the fact that the efficiency of production can be increased.

Features of the VX1000 HSS

This large format 3D printer measures a build size of 1000 x 540 x 180 mm, which inspires users to be able to produce parts with a maximum length of 1000 mm. The resolution of 360 dpi offers parts of a consistently high quality. You can use this 3D printer to mass produce parts on an industrial scale, but prototyping and small and medium batch sizes are also within the realm of possibility with the VX1000 HSS. In concrete terms, this means that it can be used, for example, in the automotive, aerospace, design model and consumer goods sectors.

Another feature of the 3D printer from voxeljet relates to safety in both planning and production, which can be guaranteed thanks to the modern sensor technology. Here, intelligent process monitoring avoids possible sources of error and points them out. In addition, you can benefit from optimal continuous operation with the VX1000 HSS, because this machine is suitable for industrial multi-shift operation.