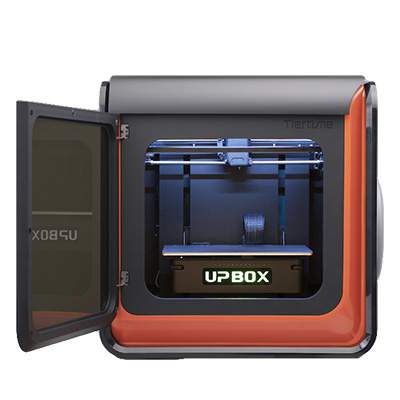

The UP Box + 3D printer comes from Chinese manufactuer Tiertime. Like the other 3D printers in the line, it uses MEM (Melted Extrusion Modelling) technology, a process similar to FDM. With 3D printing solutions such as the Up 300, Up 600 and Up Mini 3, the company is expanding its portfolio of 3D printers that use the thermoplastic material extrusion process. Accurate and stable, the BOX+ was imagined to be capable of printing detailed prototypes and end-use parts with minimal visibility of layer lines in a variety of materials.

Features of the UP Box +

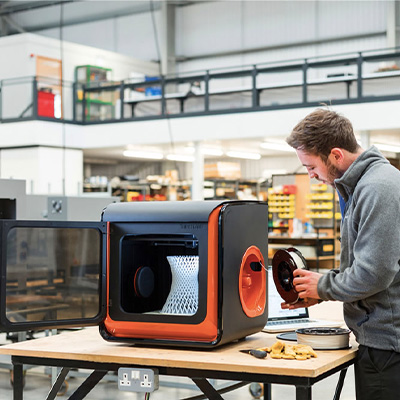

The UP Box+ is similar to other printers in the UP range, with the main differences being in its larger dimensions. It can create parts up to 255 x 205 x 205 mm, with the printer itself measuring 493 x 517 x 493 mm and weighing 20 kg. It’s compatible with a range of thermoplastics such as PLA, ABS, PETG, PET, and even specialty materials like nylon, wood, and bronze, according to Tiertime. The UP Box+ also includes an air filtration system to remove volatile organic compounds and ensure a safer working environment. It also features an end-of-material detection system, which suspends printing if it runs out of filament until it can be replaced.

The UP Box+ is equipped with electronic sensors and probes that automatically detect the nozzle height and tray level. It works seamlessly with UP Studio software and the UP Studio app, which were specifically designed for UP printers. These tools allow users to take full advantage of the printer’s features, such as setting up prints, adjusting smart media creation, importing a wide variety of file formats, and performing maintenance tasks, all in one easy-to-use interface.