The Trumpf Group is a company headquartered in Ditzingen near Stuttgart and is one of the world’s largest suppliers of machine tools. Among other things, the innovative company also focuses on the development of 3D printers. Trumpf is the only manufacturer in the world to offer both Laser Metal Fusion (LMF) and Laser Metal Deposition (LMD) technologies in its 3D printer series. The TruPrint 5000, in particular, is described by Trumpf as a highly productive and semi-automated 3D printing system that allows users to achieve industrial series production. Together with the TruPrint 1000, TruPrint 2000, and TruPrint 3000, it represents an optimal solution process for 3D printing.

Application Areas and Features of the TruPrint 5000

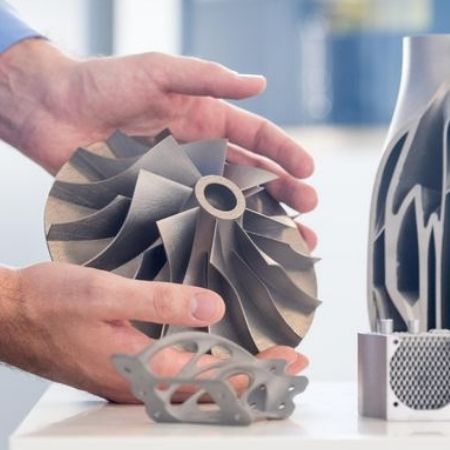

The main fields of application for the TruPrint 5000 are aerospace, tool and mold making, and medical technology. For example, thanks to Trumpf technology, you can benefit from material and weight savings in the aerospace sector, and this also opens up new possibilities in design, especially in the construction of solid components. For medical technology, the TruPrint 5000 allows you to take advantage of high customizability and the highest material requirements.

By applying 3 x 500-watt fiber lasers working simultaneously everywhere in the build space, optimal surface quality is ensured without seams and thus guarantees maximized productivity. In addition, the TruPrint 5000 impresses with its production of high part quality and a robust build process. This is made possible by the optional preheating of the substrate plate (up to 500 °C) and relates especially to applications and materials from the tool and mold production, the aerospace, and the medical industries. Thanks to this option, the TruPrint 5000 requires fewer support structures and stress cracks in titanium, and the option of an automatic process start. That means in concrete terms that this enables fast setup and offers a high level of process reliability.