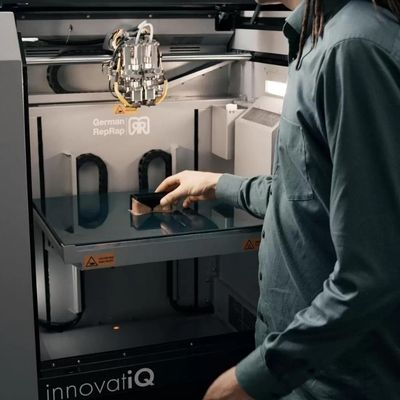

The TiQ 5 from German company innovatiQ, a member of the Arburg family since 2020, is an industrial 3D printer that uses Fused Filament Fabrication (FFF). The manufacturer specifies the following as materials that can be used: ABS, PA, PP, PC, ASA, PETG and TPU. The TiQ 5, which is intended for the production of large functional parts, has been equipped with features such as laser-assisted system leveling, meaning that physical adjustments are unnecessary. This contributes to the cost-effectiveness of the entire production process, but is also complemented by a maintenance-friendly operating concept. At the same time, users gets quick access to any technical components, which inspires them to reduce operating costs.

Other Features of the TiQ 5 3D Printer

The TiQ 5 from innovatiQ has a build area of 500 x 400 x 450 mm, while the size of the printer itself is 1246 x 974 x 1152 mm (without dryer) or 1246 x 974 x 1861 mm (with dryer). With a printing speed between 10 and 150 mm/s and a layer thickness of at least 0.02 mm, it is possible to choose between the following nozzle options: 0.25; 0.30; 0.50; 0.60 or 0.80 mm. Also, important to note is that this 3D printer is relatively quiet, with the sound during printing coming out to just around 70 dB.

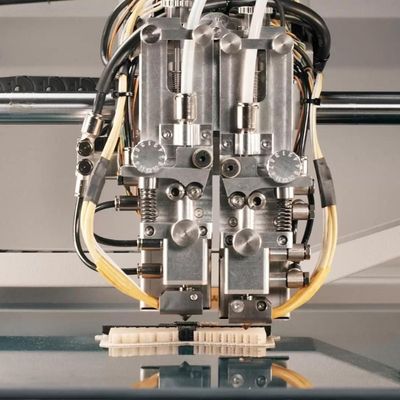

The manufacturer of this 3D printer states that the extruder is a water-cooled dual print head. This water cooling guarantees consistent precision for the user at all times – regardless of whether it’s continuous operation or one-off production. Speaking of the print head, it is also important to mention that depending on the material and application, the print head can be equipped with different nozzles such as tungsten copper. The TiQ 5 uses innovatiQ’s own internally developed nozzle technology, which enables the processing of fiber-reinforced and abrasive materials. You can also benefit from the 3D printer’s intelligent tracking system, as it monitors the printing process throughout, so you don’t have to worry about an interruption in the material supply. In doing so, the system targets material consumption and automatically makes adjustments to material feeds.