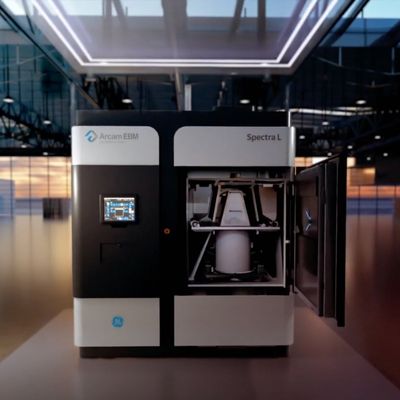

In 2019, Arcam launched its 3D printer called Spectra L as part of GE Additive. This accordingly joins the 3D printer manufacturer’s portfolio, which additionally includes the Arcam A2X, Spectra H, Q10plus and Q20plus printers. Just like its fellow 3D printers, the Spectra L is an industrial 3D printer that uses the electron beam melting (EBM) process. It’s important to note, however, the significant difference between it and Arcam’s other machines: the Spectra L offers the largest build volume at 350 x 430 mm (Ø/H), allowing its user to produce larger parts. However, due to the EBM functions, tight arrangements of parts can also be made possible, which means that you can mass produce without sacrificing quality. This large-format 3D printer, which uses metals as materials, has a hardware size of 1,328 x 2,344 x 2,858 mm and a total weight of 2,915 kilograms.

Other Features of the Spectra L 3D Printer

You should know about the Spectra L that this 3D printer is especially designed for economic benefits. For example, this machine allows for higher productivity, as it can reduce the cost factor per part by up to 20% while increasing speed by up to 30%. These benefits are due to the increased beam power of 4.5 kW, on the one hand, and the improvements in beam control, on the other. You should also know that the Spectra L has a special hardware and software system. This includes, first, Arcam EBM xQam™

Technology, which provides extremely precise beam auto-calibration. In addition, the Arcam EBM LayerQam™ offers you a monitoring system that works camera-based. Here you can benefit from comprehensive fault diagnosis as well as detailed reports. In this way, you are optimally informed about the existing errors.