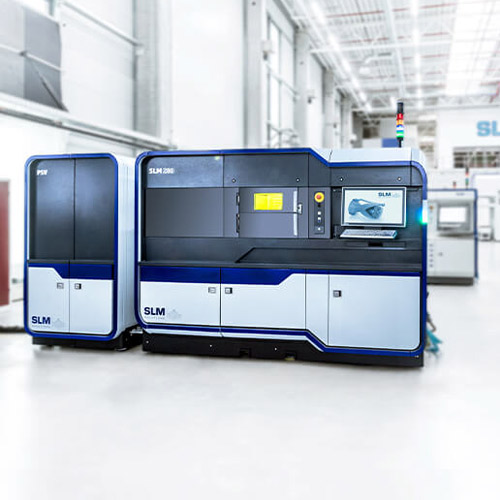

SLM Solutions, a German manufacturer of industrial 3D metal printing solutions, has released the third generation of its metal machines, the SLM®280 Production Series Solution. The company is a leader in the metal additive manufacturing industry, with a strong global presence and a range of reliable and automated solutions designed for demanding industries such as aerospace, automotive, and medical. The SLM®280 Production Series includes models such as the SLM®280 2.0, SLM®500, and SLM®800, which differ in the size of the printing plate and the number of lasers available.

Features of the The SLM®280 Production Series 3D printer

The SLM®280 Production Series 3D printer has a printing plate of 280 x 280 x 365 mm and a machine size of 4,150 x 1,200 x 2,525 mm, weighing 1,700 kg without the powder. As an industrial machine, it requires a secure working environment. The printer can be equipped with one or two lasers of 400 or 700 W power, depending on the specific requirements of the user.

The 3D metal printer offers a safe solution for powder management, ensuring a high-quality material and reducing production times and direct handling of the powder, which increases operator availability and safety. The SLM®280 Production Series also features a “Permanent Filter Module,” which filters out soot and waste from the printing process, resulting in reduced consumable costs and consistent quality, critical for repeatable production processes. The printer is accompanied by an Automatic Powder Supply Module (PSV) station, which manages all the powder required for production in a closed environment.