Velo3D, a leading manufacturer of high-performance metal additive manufacturing machines, recently launched its Sapphire XC Printer, a powerful 3D printer designed for the aerospace and defense industries. The latest product in the line of the Sapphire family is the Sapphire XC, an upgraded version of the company’s Sapphire XC 1MZ printer, and which offers enhanced capabilities for printing large parts.

Characteristics of the Sapphire XC

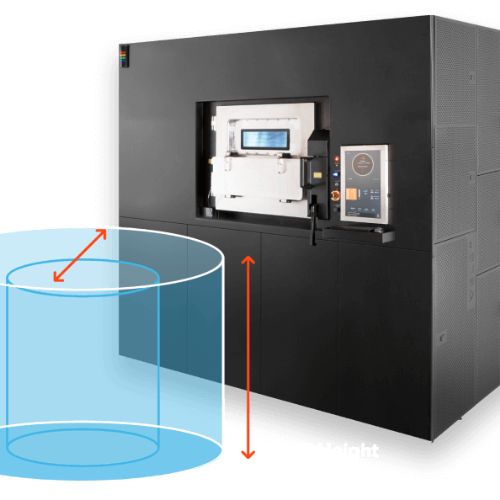

The Sapphire XC 3D printer is equipped with a large-format build chamber that measures 600mm x 550mm, enabling it to print parts up to 550mm in height and 600mm in diameter. This printer is powered by Velo3D’s Intelligent Fusion technology, which includes a proprietary print preparation software suite and real-time process monitoring for quality control. Not only that, but Velo3D is well known for its end-to-end manufacturing solution, which integrates different software to make printing easy. Not only Intelligent Fusion but also the Flow™ print preparation software which imports and reads the design, helping to prep the part for Velo3D’s SupportFree™. There is also the Assure™ software for quality validation, important when working in safety-critical industries and part of the reason why Velo3D’s solutions are so popular in those sectors.

The printer also features an improved recoater system, which enables faster and more uniform powder spreading for better build quality. Additionally, the printer is compatible with a range of high-performance alloys, including titanium, aluminum, and nickel-based superalloys, making it a versatile option for demanding applications in the aerospace and defense industries. These qualities make it an ideal choice for high-volume production of large, complex parts. The Sapphire XC Printer is designed to meet the stringent requirements of different industries, notably those that demand high-quality, reliable parts with exceptional performance characteristics. The Sapphire XC and Sapphire XC 1MZ offer the same cutting-edge capability found throughout the Sapphire line, but they also boost productivity by expanding the build volume to 600 mm by 1000 mm z-height. Users benefit from up to four times an increase in productivity and 75% cost savings when compared to the original Sapphire system.