British manufacturer Renishaw has been a leading technological solution provider since its founding in 1973. Though initially focusing on coordinate-measuring machines, the company quickly branched out into other sectors before entering metal additive manufacturing in 2011. Currently, the company has 77 offices in 36 countries, with over 5,000 employees worldwide (including 3000 based in the UK).

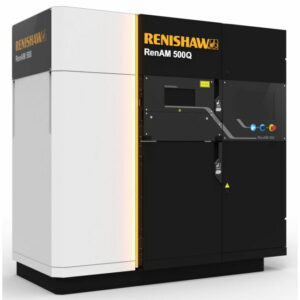

In terms of metal additive manufacturing, Renishaw has quickly made a name for itself in the field. Currently, it offers its RenAM 500 line of metal 3D printers, consisting of the RenAM 500Q, RenAM500S and RenAM500 Flex. All use metal powder bed fusion technology for all their machines. In terms of applications, they are involved in a number of sectors but have gained recognition in recent years especially for work with British Cycling in creating better bicycles using metal 3D printing for international competitions like the Commonwealth Games and the Olympics.