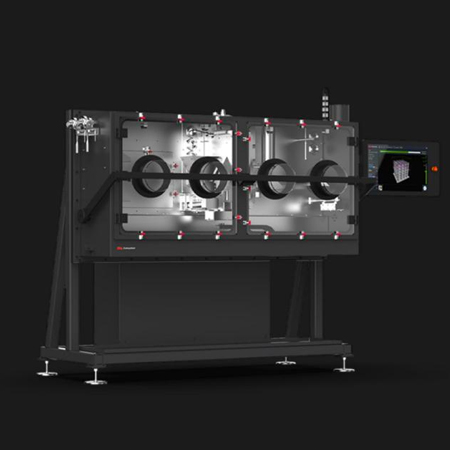

US-based Desktop Metal has introduced the P-1 Production System™, a metal 3D printer catering to industrial applications. Using the manufacturer’s Single Pass Jetting™ (SPJ) binder jetting technology and incorporating a bidirectional 3D printing system, it boasts an impressive speed that accelerates metal parts’ additive manufacturing by a factor of 100, setting it apart from other options available in the market.

Features of the P-1 Production System™

The P-1 Production System™ is purpose-built for mass production, featuring a maximum production volume of 200 x 100 x 40 mm. Powered by Desktop Metal’s SPJ technology, it supports both reactive and non-reactive metal powders, providing a versatile platform for small and intricate batch production. With external dimensions measuring 1770 x 2007 x 1150 mm, the printer combines quality and consistency while offering enhanced process flexibility.

One of the notable highlights of the P-1 Production System™ is its open material platform and the company’s choice of binders, allowing for 3D printing with an extensive array of metals, ranging from stainless steels to high-performance alloys. As a result, Desktop Metal’s innovative solutions are driving metal 3D printing to the forefront of industrial additive manufacturing.