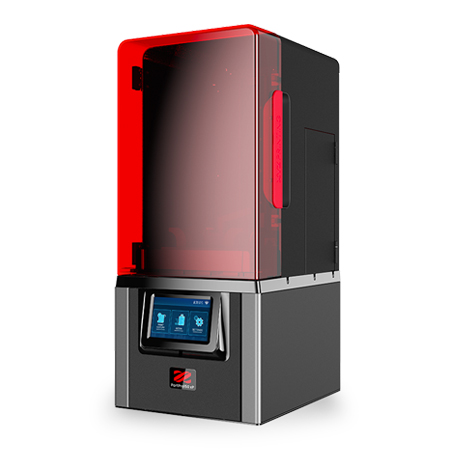

Founded in 2013, the Asian company XYZprinting has been setting standards in desktop and professional 3D printing for years. In addition to advanced solutions based on various technologies (powder bed, extrusion), it has also developed a range of professional machines based on a resin process. XYZprinting’s PartPro range consists of the 100 xP, the 120 xP and the 150 xP, all based on the resin process. Let’s now take a look at the features of the PartPro150 xP.

Features of the PartPro150 xP

The PartPro150 xP is based on stereolithography (SLA) technology and features a linear laser scanning system that ensures higher quality and reliability compared to conventional galvo mirror systems.

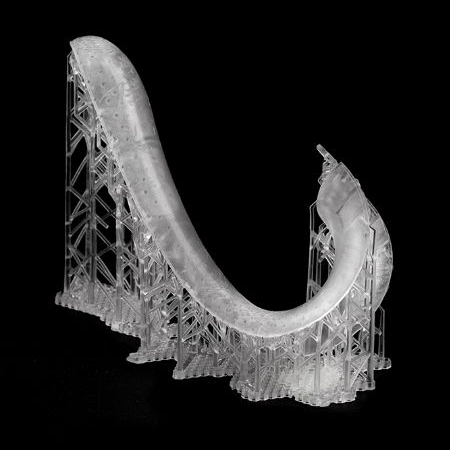

It has a maximum print volume of 150 x 150 x 200 mm, a weight of 15.5 kg and a layer resolution of 25 / 50 / 100 microns. Other features of this device include touch screen control, enclosed housing and USB, Ethernet or wireless connectivity. Compatible with the manufacturer’s resins and its XYZprint AM software, the PartPro150 xP is a high-resolution 3D printer ideal for producing all types of parts and accelerating users’ ideas. The larger build area in particular is useful for parts which require smooth surface finishes, from consumer goods to jewelry. The XYZPrinting website gives some examples of parts which can be made using the PartPro150 xP: a buckle, eyewear, and a handheld scanner. All of these parts have a complex geometry, thus demonstrating the capabilities of the machine.

As with the other PartPro printers in the series, the printer is available in multiple languages. The tank is coated with a resin which extends the printer longevity and ensures quality printing in the long term. Finally, the printer has hands-free auto-calibration, making it more user-friendly.