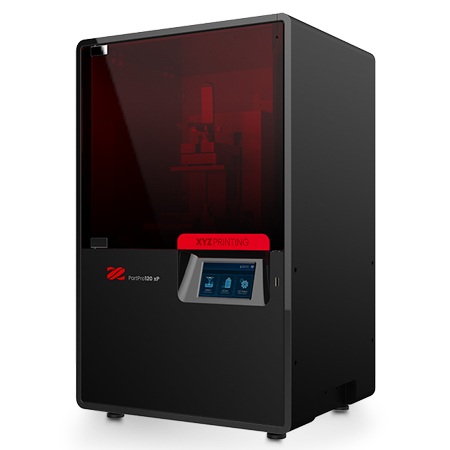

Founded in 2013, the Asian company XYZprinting has been a benchmark in both desktop and professional 3D printing for years. In addition to having advanced solutions based on different technologies (powder bed, extrusion), it has also developed a line of professional machines based on a resin process. XYZprinting’s PartPro range consists of the 100 xP, the 120 xP and the 150 xP, all based on resin methods. Let us now take a look at the properties of the PartPro120 xP.

Features of the PartPro120 xP

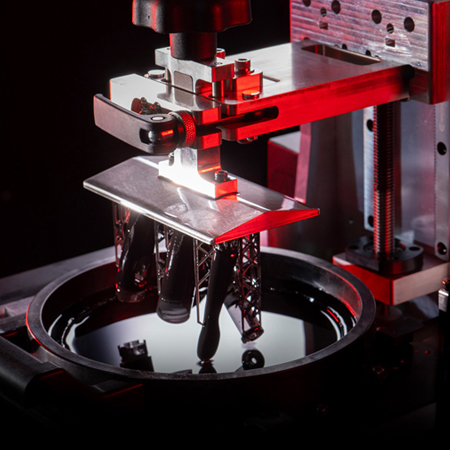

The 3D printer is based on a combination of UFF (Ultra Fast Film) and DLP (Digital Light Processing) technology. On the one hand, the DLP method uses a digital micromirror device to reflect and focus UV light on the surface of the photosensitive resin, which is cured layer by layer. The UV light source is λ (wavelength) 405 nm. Aside from DLP, the UFF technology enables high-performance 3D printing.

The PartPro120 xP has a maximum printing volume of 114 x 64 x 100 mm, a weight of 11 kg and a layer resolution of 25 / 50 / 100 microns. In addition, other features of this machine is that it has a touch screen control, an enclosed enclosure and USB, Ethernet or wireless connectivity. Compatible with the manufacturer’s resins (ProUtility / ProAccure / ProBlueHS / ProFlexDL / Eeezcast+) and its XYZprint AM software, the PartPro120 xP makes it possible to create high-resolution final parts in a matter of minutes.

The printer is available in multiple languages and supports the following file formats: stl / .igs / .stp / XYZ format (.3ws / .3wn)

Examples of parts which can be made using the PartPro120 xP are a toothbrush handle made of the proprietary ProBlueHS resin. The printer can also be used to make jewelry: the EeezCast+ castable resin offers a high-performance jewelry design process and a high-quality end product.