Founded in 2013, the Asian company XYZprinting has been setting standards in desktop and professional 3D printing for years. In addition to advanced solutions based on various technologies (powder bed, extrusion), it has also developed a range of professional machines based on a resin process. XYZprinting’s PartPro range consists of the 100 xP, the 120 xP and the 150 xP, all based on the resin process. Let’s now take a look at the features of the first machine.

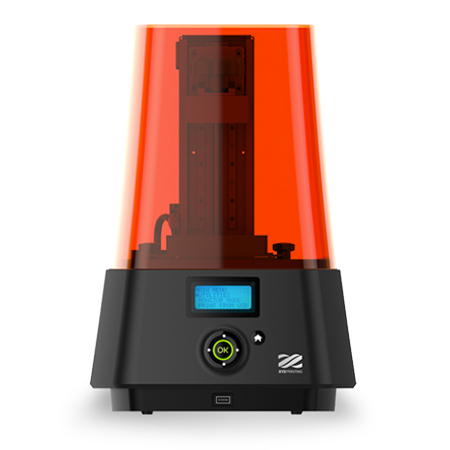

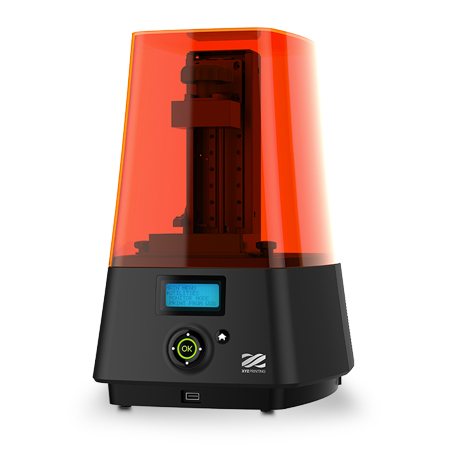

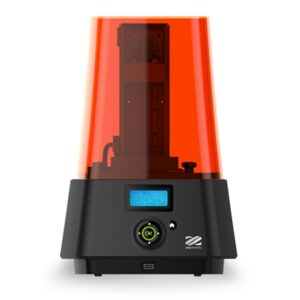

Features of the PartPro100 xP

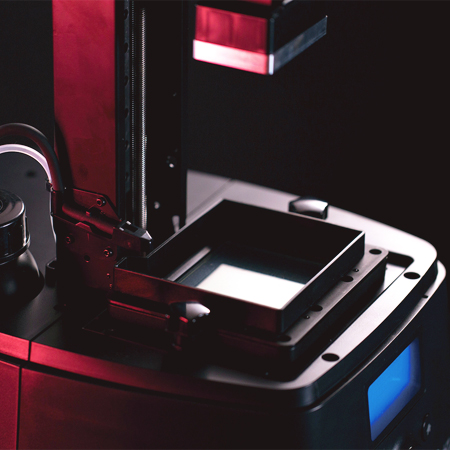

This machine is based on Digital Light Processing (DLP) resin technology and uses a digital micromirror device to reflect and focus UV light onto the surface of the photosensitive resin, which is then cured layer by layer.

It has a maximum print volume of 64 x 40 x 120 mm, a weight of 11 kg and a layer resolution of 25 / 50 / 100 microns. Other features of this device include touch screen control, enclosed housing and USB or wireless connectivity. Compatible with the manufacturer’s resins and its XYZprint AM software, the PartPro100 xP is a high-resolution 3D printer ideal for producing small parts where precision and detail are critical.