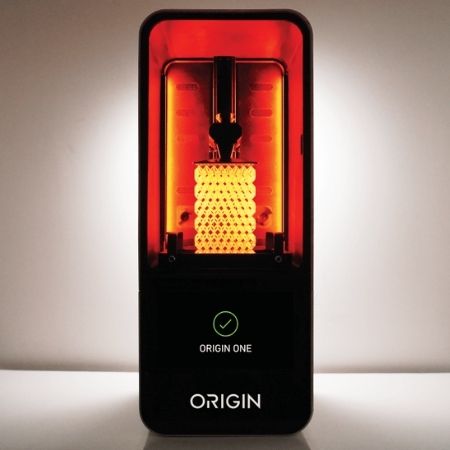

In December 2020, US 3D printing giant Stratasys struck the additive manufacturing market by acquiring Origin. Through this acquisition, which was worth a total of over $100 million, Stratasys entered the field of mass production of resin-based consumer parts. In fact, the additive manufacturing specialist has expanded its extensive line of machines to include the Origin One, a 3D printer that can produce large parts with precision and speed, all with a wide selection of resins.

Features of the Origin One

Launched in 2019, the Origin One quickly impressed with its ability to use industrial-grade resins to produce parts for mass production. The printer offers a print volume of 192 x 108 x 350 mm and is based on a process called programmable light curing, or P³, an advance on digital light processing (DLP) principles. The Origin One controls the light required to cure the liquid photopolymer resin, the heat, and other parameters using Origin’s closed-loop feedback software. It also uses computer vision and more than 25 environmental sensors to monitor and respond to all key aspects of the printing process. In-situ analysis, combined with automatic control of pressure, tension, and temperature, ensures that the first part is identical to the last.

Finally, in terms of applications – from biocompatible medical devices to aerospace-grade components – the Origin One paves the way for revolutionary production applications, according to the manufacturer.