The Omni500 Lite is manufactured by Omni3D, the first Polish manufacturer of industrial FFF 3D printers. Founded in 2013, the firm released the Omni500 LITE in 2019, marketed as ‘The ideal solution for Users who demand fast and simple production meeting industrial standards.’ The manufacturer has quickly grown, currently offering six solutions and is available in a number of different countries including Australia and the UK.

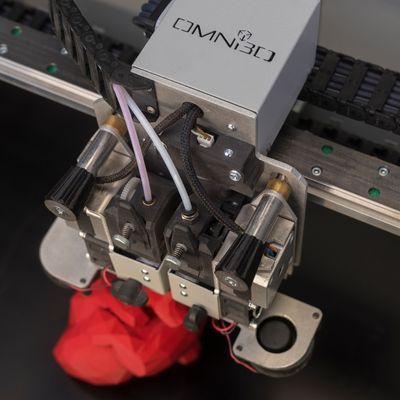

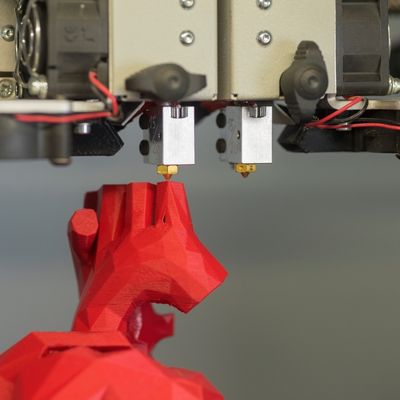

The Omni500 Lite in particular has been designed for large-scale FFF 3D printing. Its build volume of 460 x 460 x 600 mm offers users the option of printing larger objects or several smaller models at once. Moreover, the printer comes with two extruders enabling the user to print both the object and the support simultaneously, which are equipped with a filament presence sensor. The printer has a maximum platform temperature of 130ºC, and a maximum chamber temperature of 50ºC. The Omni500 LITE is compatible with a number of file formats: .stl, .obj, .3mf, .gcode, .factory. More importantly, the printer has CE certification and comes with a 12-month warranty which can be renewed.

Features of the Omni500 LITE

The Omni500 LITE comes with a number of features that make it ideal for industrial FFF 3D printing. Notably, we can point to the inclusion of Omni3D Web Control™ which allows the user to monitor and make changes remotely during the printing. This, as we know, is crucial for industrial 3D printing as it gives the user greater control over the printing itself, reducing the chance for print failures and increasing print quality.

Furthermore, the printer comes equipped with the Omni3D Head Leveling Control™ and the Omni3D Platform Autoleveling System™. Working together, these software ensure optimal conditions for the part during printing for more accurate results. The hardware also plays a role. For example, new head radiator cooling system improves the temperature control of the heads; this results in better filament extrusion and a higher quality end product. Furthermore, the inactive head lifting system automates calibration of the head which improves print repeatability and allows you to work with geometrically complex designs without risking damage to the print out. The final special feature is the aluminum two-sided milled structure of the platform. This ensures maximal surface flatness; essential to the quality of the finished product due to high precision.

As shown on the Omni3D website, the Omni500 Lite can be used for multiple applications, including the manufacture of spare parts, of optimally comfortable face shields, to name two examples.