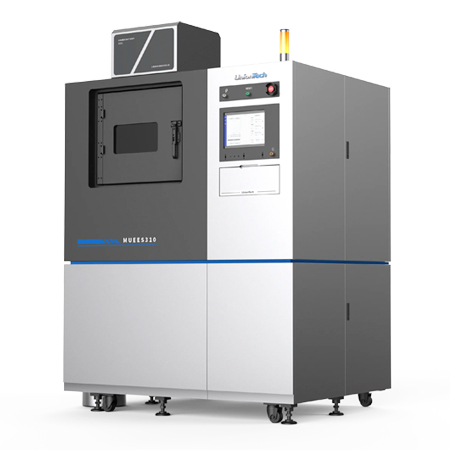

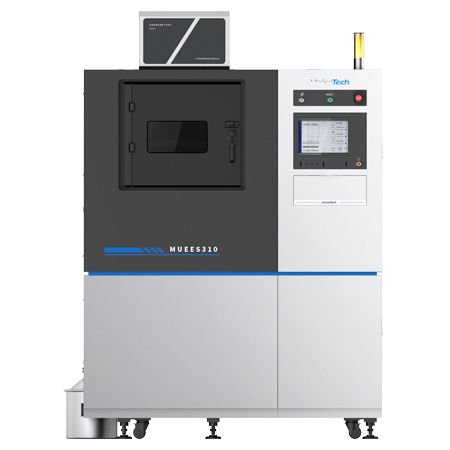

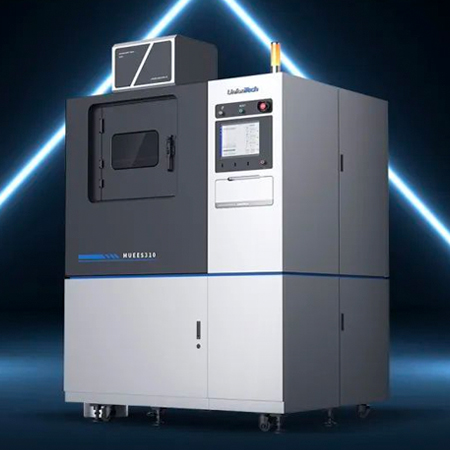

China-based manufacturer UnionTech is known for its resin 3D printing solutions based on different technologies (SLA, DLP, LCD). However, it also has several metal machines that create 3D parts using SLM (Selective Laser Melting). Among them is the Muees310 3D printer, an industrial-grade solution with the ability to create metal parts with high precision.

Muees310 Features

The Muees310 is an industrial-grade SLM 3D printer that has been designed to offer a metal parts manufacturing process with high efficiency, precision and stability. It has a total weight of 2000kg and outside dimensions of 1845 × 1405 × 2640 mm. With a layer thickness between 0.02 and 0.1 mm, this machine integrates 1 x 500 w / 2 x 500 w ytterbium lasers for the creation of high-quality parts. The 3D printer has a maximum print volume of 310 x 310 x 400 mm and is compatible with a wide variety of metals.

This metal solution has outstanding properties to provide a safe and optimized manufacturing environment. On the one hand, built-in valves and ventilation ensure safety during printing. On the other, the integrated air filtration system prevents secondary contamination, while the double-sealed piston ensures the tightness of the metal powder magazine. Finally, the Muees310 is compatible with a complete process software system developed in-house.