HAGE3D is an Austrian company that is based in Styria. Since entering the 3D printer market in 2019, it has produced a variety of 3D printing devices. Aside from its serial models that include the MEX ONE, HAGE3D 140L and HAGE3D 175C, the company also focuses on the development of special solutions for the industrial manufacturing market. These special 3D printers provide users with individual and precisely fitting 3D solutions that adapt to any kind of industrial challenge. In addition to the MEX PROLINE, the product line also includes the HAGE3D 175 CONVERTIBLE. With both models, the user experiences the advantages of large, enclosed, and temperature-controlled installation spaces, in-house material and application centers for process reliability, and modular machine systems thanks to exchangeable print heads.

Features of the MEX PROLINE

By introducing the PROLine, HAGE3D provides a solution that is able to print directly on plastic parts, textile,s or other materials, adding 100% value as a production line within additive series manufacturing. The size of the built-in envelope is up to 300 m (Y), up to 600 mm (Z), and for the X-axis, HAGE3D offers of an endless conveyor belt, which definitely makes the MEX PROLINE its special solution. The installation space, which can be heated up to 50 °C, has a positioning accuracy of less than 0.1 mm as well as an optional individual automatic calibration of the print bed measurement before each print.

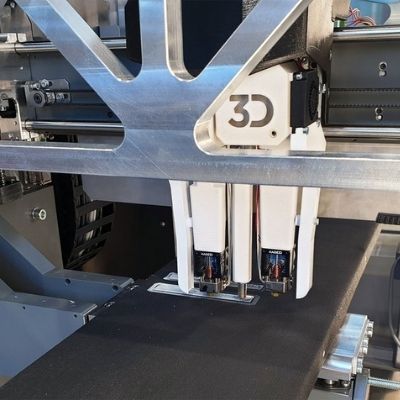

The print head of the MEX PROLINE is equipped with air cooling and has a nozzle diameter of 0.2 to 1.0 mm, with the standard being 0.4 mm. The layer thickness starts at 0.05 mm and depending on the geometry and the material, the 3D printer by HAGE3D reaches a printing speed of 90 mm/s. Other useful features are first and foremost the smart stop-and-go function, which allows printing to be paused quite easily. Furthermore, users can enjoy the multi-level user level and an LED +7″ touchscreen.