Massivit is a manufacturer of large-format 3D printers that has developed two proprietary technologies: Cast In Motion (CIM) and Gel Dispensing Printing (GDP). Massivit’s 3D printers are used in the automotive, aerospace, railway, naval, education and research, sports equipment, and entertainment sectors. They are known for their printing speed, the size of the produced parts, and their isotropy.

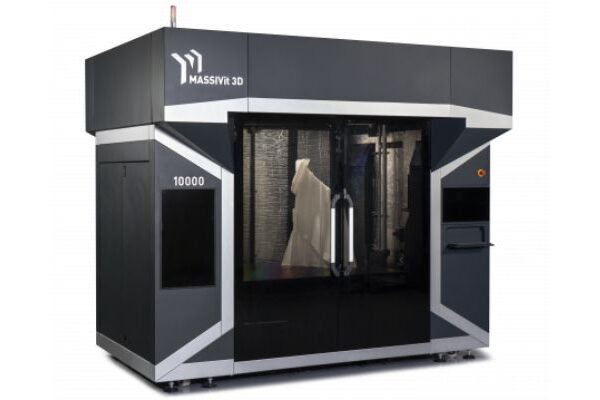

Features of the Massivit 10000 Range

Equipped with the manufacturer’s CIM technology, the Massivit 10000 features a dual-head system. The first head prints a high-speed dissolvable outer shell, while the second head melts a high-performance thermosetting material (an epoxy), also provided by Massivit, into the same shell. The shell consists of two thin water-soluble walls made of photopolymers, which harden when exposed to ultraviolet light. Once the object is printed, it is baked in an oven (thermosetting) to reinforce its mechanical properties before being immersed in water to dissolve the shell.

The industrial 3D printer Massivit 10000 aims to automate the production of molds for composite materials and address bottlenecks. The Massivit 10000 can be used to print tools and various types of molds, including complex custom molds such as thermoforming molds, thermoplastic composite molds, resin transfer molding molds, and reaction injection molding molds. Furthermore, the costs and time required to manufacture the molds are reduced compared to traditional subtractive manufacturing processes. Additionally, the CIM technology ensures that the produced mold is truly isotropic, a world first according to the manufacturer. The isotropy of the mold guarantees that the mechanical and thermal properties of the object are identical across its entire surface.

Thanks to the inclusion of Gel Dispensing Printing (GDP) technology, the Massivit 10000-G model also offers applications for custom manufacturing and functional prototyping.