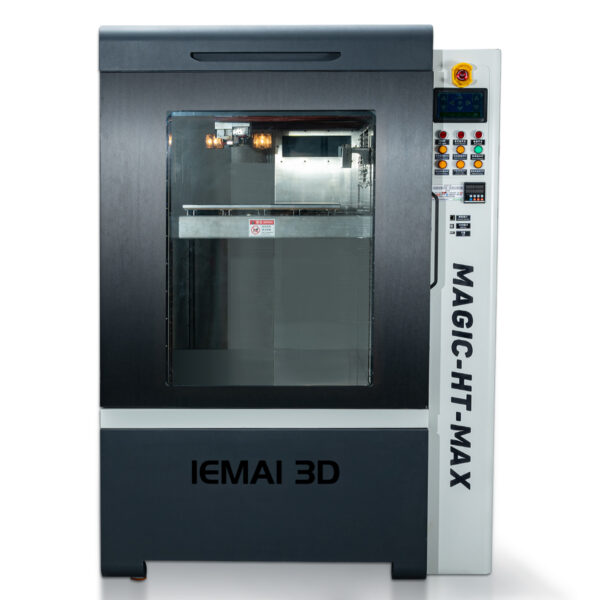

Chinese manufacturer IEMAI 3D offers complete solutions for industrial 3D printing. It is notable for its compatibility with a wide range of materials, notably high-performance polymers. The application areas are also varied, including in the automotive, aerospace and medical technology industries. Not to mention, their solutions are also used in the electrical and oil industries. The MAGIC-HT-MAX 3D printer is a solution using FFF technology that was developed in 2019.

Features of the MAGIC-HT-MAX 3D Printer

As might be expected from an industrial printer, the MAGIC-HT-MAX 3D printer incorporates a number of useful features. These include (but are not limited to) a liquid cooling system, a filament run-out sensor, a built-in camera, automatic nozzle cleaning and the ability to recover the print in the event of a power failure. Furthermore, it is equipped with a humidity-resistant compartment for filaments, integral to prevent damage to polymer filaments, that is controlled at 10-15%. This compartment can be heated up to 65 ℃, so that the filament remains dry during printing. Its maximum print volume is 500 x 500 x 700 mm, which is one of the largest manufacturing volumes for a machine with these features. The dimensions of the MAGIC-HT-MAX are 1080 × 1380 × 1950 mm and its weight is 750 kg, while a printing speed of 150 mm/sec is achieved. Among the materials with which it is compatible are: PEEK, PEKK, ABS, ASA, among others.

The manufacturer recommends using the company’s slicer, IEMAI3D EXPERT. However, the 3D printer is also compatible with other software such as Cura or Simplify3D. In addition to the features already mentioned, the machine also has automatic calibration, a dual extruder, a control screen and a fully sealed chamber. There is no doubt that this 3D printer is an excellent industrial solution for the production of high-performance parts.