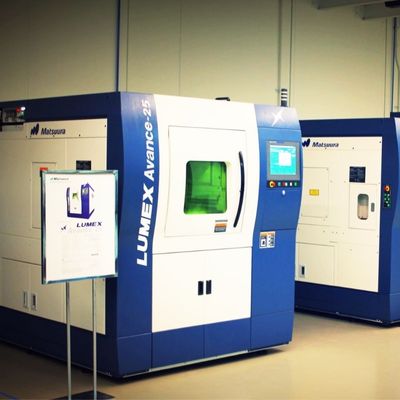

Based in Fukui, Japan, Matsuura Machinery Corporation focuses on the development and manufacture of 3D printers, among other things. Specifically, this is their LUMEX series, which includes the LUMEX Avance-60 launched in 2016, as well as the 2017 LUMEX Avance-25, both of which use metal 3D printing. So, as far as the LUMEX Avance-25 is concerned, according to the manufacturer, there are two possible options as far as the final 3D-printed part is concerned: on the one hand, the standard version, which allows the user to produce a part weighing a maximum of 90 kilograms and measuring 256 x 256 x 185 mm; on the other hand, the advanced option. Here, parts with a maximum weight of 150 kg and dimensions of 256 x 256 x 300 mm can be achieved.

More details about the LUMEX Avance-25

As far as the power of the laser is concerned, Matsuura again distinguishes here between a standard version with a 500W laser or the version with a 1kW. If we continue to talk about the power of the laser, then the manufacturer also shares that an improved powder distribution speed is given. In terms of the powder material, it is also important to mention that both the supply, collection and reuse of the powder is completely automated. In concrete terms, this means that the excess powder is sieved by the automation and thus recycled for further printing operations. However, this system, the Automatic Powder Recovery (APR) system, is only available in the optional version.

This machine, which uses SLM/DMLS technology, is a hybrid industrial 3D printer that weighs 4,500 kilograms. Moreover, this model is not only capable of printing metal parts, but also has an integrated milling machine, so users can benefit from a complete manufacturing method. The maximum build speed is 35 cc / h. The printer is suitable for a range of industries, including aerospace and defense, prototyping, and medical.