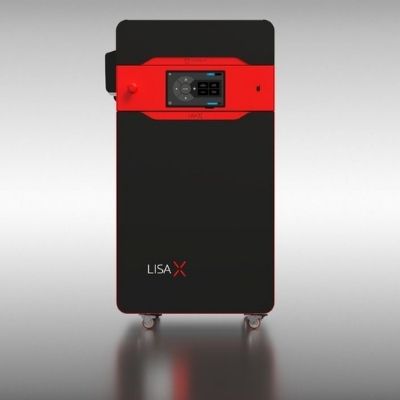

The Lisa X SLS 3D printer was developed by Polish company Sinterit and is part of the line of compact 3D printers that includes the Lisa and Lisa PRO, as well as the NILS 480 industrial printer. According to the manufacturer, the printer, which uses selective laser sintering (SLS), is not only faster in terms of printing, but is a large model despite its compact size. The Lisa X 3D printer was developed with the goal of allowing additive manufacturing users the freedom to innovate better and faster. In terms of speed, the print speed can take on up to 14 mm/hr – meaning that with the ability to print up to five print beds per week, users can prototype and iterate a lot faster.

Characteristics and Features of the Lisa X

With a print bed of 130 x 180 x 330 mm, the Lisa X is the largest compact SLS 3D printer offered by Sinterit. This allows the user to easily print either a greater number of parts at once or larger objects. The printer uses Sinterit Studio software and supports the following file types: STL, 3MF, OBJ, 3DS, FBX, DAE. As for the software, the manufacturer states that you can choose between either Sinterit Studio or Sinterit Studio ADVANCED. The differences between the two software refer to the possibility of using third party materials as well as modifications to the printing parameters.

In addition, Lisa X has 16 independent heating elements divided into four modifiable zones: Pressure Chamber, Pressure Area, Cylinder and Piston. The maximum temperature in the pressure chamber is 210 °C. It is also compatible with nine materials, from ultra-durable, flexible materials to more specialized ones for an even greater number of applications. An additional benefit when it comes materials is that it has an open printing system, meaning that users can use materials other than those produced by Sinterit. And though there are no pre-defined parameters (making it easier to use materials from other manufacturers), for flexibility it is possible to print with Sinterit’s recommended printing settings.