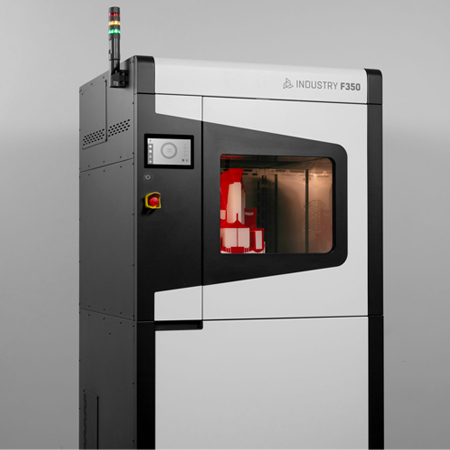

Since 2014, the European company 3DGence has been offering versatile, flexible and cost-effective industrial 3D solutions to support and optimize the workflow of professionals working in various industries. To this end, the company also develops high-performance materials, which stand out for their strength, lightness and cost. Since its beginnings, 3DGence has offered extrusion-based machines for a variety of industries, such as the 3DGence One, INDUSTRY F420, INDUSTRY F421 and of course the INDUSTRY F350 3D printers.

Features of the INDUSTRY F350

With a print volume of 340 x 340 x 350 mm, this dual extrusion printer has been developed for industrial applications where precision, speed, convenience and safety throughout the 3D printing process are essential. Compatible with a wide range of engineering materials, including high-performance thermoplastics, the F350 is designed also for versatility. With a heated print chamber that can be heated up to 180°C, the 3D printer is suitable for a wide range of industries, such as aerospace and automotive. The machine incorporates an intelligent filament management system, which allows it to recognize the material, its extrusion temperature, its remaining amount in grams and all information regarding the inserted spool.

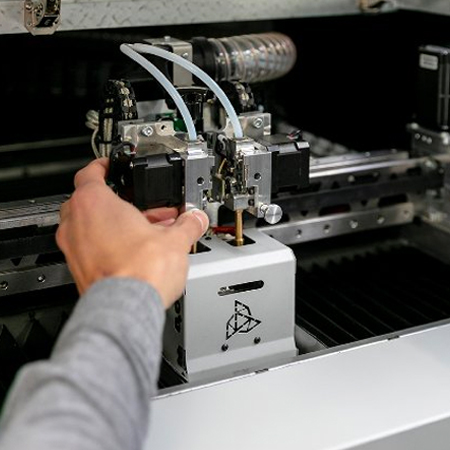

3DGence has developed several modules for the F350. The machine has three interchangeable modules to produce parts from a wide range of filaments. Of the various modules, the 280 is the most versatile. This dual extrusion module is capable of printing the most popular materials. It can also print HIPS and ESM-10 soluble supports.