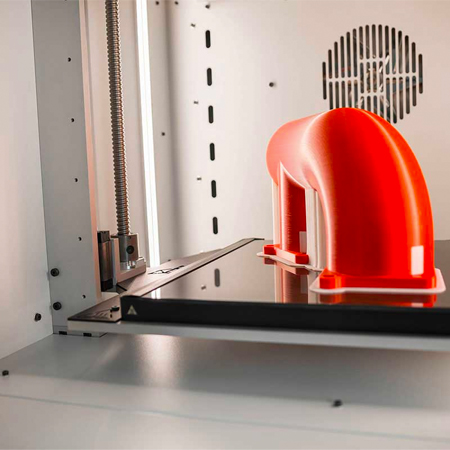

The INDUSTRY F340 from the Polish manufacturer 3DGence is the successor of its first INDUSTRY 3D printer. The INDUSTRY F340 is part of the same range as the DOUBLE P225 and 3DGence ONE. The manufacturer of these machines, 3DGence, has grown exponentially since its creation in 2014. The company’s latest model offers companies the ability to choose between different printheads to achieve the best print results with different functions.

INDUSTRY F340, different printheads for different projects

The 3D INDUSTRY F340 printer has the PRO Module head (0.4 mm) that can reach up to 265 °C, and print with materials such as ABS, HIPS, PET and nylon. It has the HT Module head (0.4 mm), suitable for manufacturing with PC, PC-ABS, PC-ESD, as this print head can heat up to 340 °C. The third printhead is the HF Modules 0.6 mm capable of manufacturing with ABS, ASA, PA-CF. Finally, it has the so-called HTmax Module (0.4 mm), that can reach up to 500 ° C to print objects with advanced thermoplastics such as PEEK. This opens up manufacturing possibilities for various companies. It has a printing volume of 260 x 300 x 340 mm and a layer resolution of up to 40 microns.

3DGence claims that the machine is the most versatile industrial 3D printer as it is compatible with the widest range of engineering materials. With the INDUSTRY F340 3D printer, users are able to manufacture high-quality, durable parts with complex geometrics. Additionally, they can take care of a number of key features such as the printers large build volume, heated printing chamber, heated material chamber or autocalibration. The printer can be used in a vast number of industries including medical, automotive, architecture and education.